Next Generation Refractory Solutions for Steelmaking through Coreless Induction Furnace

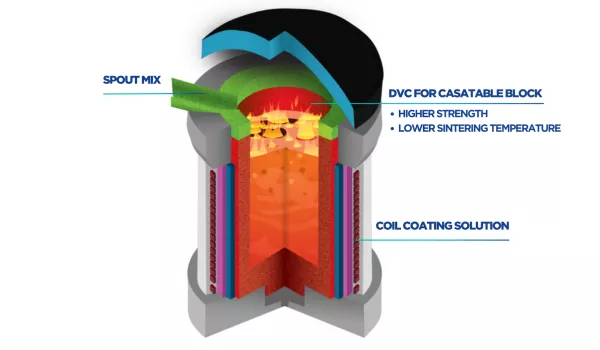

HeatKing™ introduces an advanced monolithic lining solution designed to optimize steel melting processes in coreless induction furnaces. Its unique structure guarantees superior steel quality, reduced cost per unit, improved productivity, enhanced safety, energy efficiency, and sustainability.

Our HeatKing™ range includes solutions for working linings, furnace tops, spouts, and coil coatings, enabling customers to operate with maximum efficiency and reliability.

Interested in our Products, application engineering or lining services? Click here to connect!

Solution By Application

Click on your application to find more:

- Working Linings

- Furnace Top and Spout

- Coil Coat

High Alumina Refractory Solutions for Furnace Top and Spout in Coreless Induction Furnaces

Saint-Gobain Performance Ceramics and Refractories offers high alumina-based single component refractory ready-mix, meticulously engineered for the specific demands of spout and topping applications in coreless induction furnaces used for steel melting. This innovative product addresses the unique challenges of areas above the metal level in refractory-lined induction furnaces, where achieving proper sintering temperatures can be particularly difficult. The high alumina content ensures excellent thermal stability and resistance to thermal shock, making it an ideal choice for these critical zones.

Our products, such as TA 1211 and PA 1451T, offer superior bonding capabilities, ensuring they adhere well to the existing refractory lining. This creates a cohesive and robust layer that can withstand the rigorous conditions of steel melting operations.