Wear Resistant Solutions & Technologies

Durable Ceramic Products Designed for Extreme Wear and Corrosion

Heavy industrial processes place intense mechanical and thermal stress on equipment, pushing materials to their limits. Challenges such as abrasion, high temperatures, and corrosive environments can quickly wear down equipment and disrupt productivity, leading to unplanned downtime and interruptions to workflows. Saint-Gobain Performance Ceramics & Refractories has advanced wear resistant ceramic solutions & technologies, such as alumina, zirconia toughened alumina (ZTA), silicon carbide, and silicon nitride, available that can endure the most aggressive settings and extend the life of critical components. With our advanced materials and extensive experience, we help our clients to protect their critical equipment while delivering efficient performance across a range of industrial applications, from material handling to high temperature furnace operations.

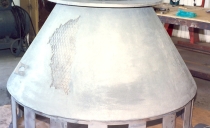

Abrasion Resistant Ceramics

Crafted from high-performance alumina, silicon carbide, and fused zirconia, our abrasion-resistant ceramics are built for continuous exposure to wear, impact, and corrosion. These engineered materials can be configured as tiles, linings, or custom components to meet specific process needs and maintain integrity under severe mechanical and thermal stress. In equipment like crushers, grinding mills, and conveyor systems, they demonstrate exceptional hardness, chemical resistance, and thermal stability, ensuring dependable performance, extended uptime, and lower maintenance costs.

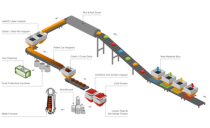

Equipment Protected with Wear Resistant Ceramics

We engineer wear resistant solutions & technologies for heavy industry that can extend equipment life and enhance performance across demanding applications:

- Blast Furnace Charging Systems – Custom linings and chutes for extreme wear.

- Crushing, Pulverising, and Grinding – Liners for reliable mineral processing.

- Separation and Screening – Abrasion-resistant components for precise classification.

- Piping Systems – Ceramic-lined parts for long-lasting flow control.

- Belt Conveyor Components – Protection for transfer points and loading zones.

- Sinter Plant Equipment – Durable ceramics for drums, decks, and hot screens.

Industry Applications for Wear Resistant Ceramics

We serve a diverse customer base that requires reliable wear protection to keep operations running effectively. Our wear resistant solutions & technologies are designed to reduce maintenance, extend service life, and enhance productivity, and so are utilised across a variety of different industries:

Comprehensive Service Capabilities

Expert support can make all the difference when it comes to minimising downtime and maximising equipment reliability, which is why we work closely with customers to ensure every wear resistant solution & technology we deliver performs at its best. You can expect the following:

Related Content

Learn more about our wear resistant solutions & ceramic technologies through our content.

Speak to an Expert

Reach out to our team for additional information about our wear resistant solutions & technologies.