Wear Resistant Technologies

Saint-Gobain Performance Ceramics & Refractories’ innovative Wear Resistance Technologies business unit, can manufacture a wide range of different high grade ceramic materials.

Wear Resistance Technologies can customize products and soliutions according to customers’ abrasion, erosion and corrosion needs. Our core objective is to ensure the optimum performance, efficiency and service life of customers’ equipment and systems; while aligning our values on sustaibability and carbon free goals.

Solution By Equipment

Click on your equipment to find more:

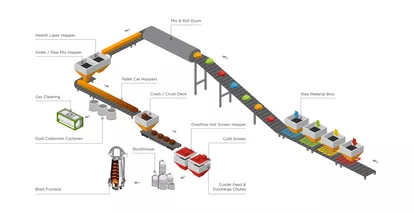

Sinter Plant

Saint-Gobain Performance Ceramics & Refractories supplies a wide range of lining types and systems to sinter plants - one of the most demanding plant systems to operate – and palletization production.

The company’s innovative wear resistance products can be found in every part of the iron ore fine sintering process; from the preparation of sinter mixtures to the recycling of the fines from the sinter plant and blast furnace.

Solutions are available for:

- Raw material preparation

- Mix and reroll drums

- Sinter machines

- Crash decks

- Hot screens

- Coolers

- Cold screens

- Scrubbers and fume emission systems

- Stock piles and stock house feed belts

Ceramic Solutions

| Alpha Al2O3 | Zirconia Toughned Alumina | |

| Durafrax® | Durastrike® ZTA | |

| Sliding Abrasion | +++ | ++++ |

| Erosion | +++ | ++++ |

| Impact | + | +++ |

| Corrosion Resistance | ++ | ++ |

| Thermal Shock | + | ++ |

| Thermal Insulation | + | + |

| Electrical Insulation | ++++ | +++ |

| Nitride Bonded SiC | Reaction Bonded SiC | Sintered Alpha SiC | ||||||||

| Cryston® | Cryston® TW | Cast Refrax® 20 | Refrax® 20 | Norfrax® RB | Silit® SKD | HAMMERfrax® | Hexoloy® | |||

| Sliding Abrasion | + | ++ | + | + | +++ | +++ | ++++ | ++++ | ||

| Erosion | + | + | + | + | ++ | ++ | +++ | ++++ | ||

| Impact | ++ | + | + | + | + | + | ++ | + | ||

| Corrosion Resistance | ++ | ++ | ++ | ++ | +++ | +++ | ++ | ++++ | ||

| Thermal Shock | + | ++ | ++ | ++ | ++ | ++ | ++ | ++ | ||

| Thermal Insulation | ++ | ++ | ++ | +++ | + | + | + | + | ||

| Electrical Insulation | NA | NA | NA | NA | NA | NA | NA | NA | ||

| Fused Cast AZS | Zirconia Toughned Alumina | |

| ZAC - Corguard® | Durastrike® ZTA | |

| Sliding Abrasion | ++ | ++++ |

| Erosion | ++ | ++++ |

| Impact | +++ | +++ |

| Corrosion Resistance | ++ | ++ |

| Thermal Shock | ++ | ++ |

| Thermal Insulation | ++ | + |

| Electrical Insulation | ++ | +++ |

| Silicon Carbide | Aluminium Oxide | |

| Wearfrax® RS58 | Wearfrax® RA57 | |

| Sliding Abrasion | + | + |

| Erosion | + | + |

| Impact | + | + |

| Corrosion Resistance | + | + |

| Thermal Shock | ++ | + |

| Thermal Insulation | ++ | + |

| Electrical Insulation | NA | NA |

Documents

FAQ

Does Saint-Gobain Performance Ceramics & Refractories have experience in installing ceramic linings on a crash deck?

Saint-Gobain Performance Ceramics & Refractories is the most experienced supplier of these linings, having supplied some of the very first crash deck installations in the late 1970s.

Designs and materials have improved and evolved over time, now outperforming many metals and other ceramics in crash deck applications.