Carbon Black

Saint-Gobain Performance Ceramics & Refractories has been a leading supplier of complete refractory linings for carbon black reactors for over three decades.

A range of custom-engineered solutions is available for hot face and backup layers in tread and carcass black reactors. These include:

- Fired or precast chrome-alumina bricks and shapes

- High purity alumina bricks in grades AH199, AL100 and Alfrax101

- Thermal shock resistant Mullfrax® and AL102 bricks

- Zirnorite® Zirconia bricks for the highest temperature capability

- Fused-cast Jargal M shapes for ultimate erosion resistance

- Insulating and dense castables for backup layers

Solution By Reactor-based Solutions

Click on your equipment to find more:

- Tread Reactor

Carbon Black Tread Reactor

Saint-Gobain Performance Ceramics & Refractories is a global leader in refractory solutions, specializing in technologies for carbon black production. Carbon black tread reactors are specialized vessels used in the industrial production of carbon black, which is a key material in tire manufacturing. These reactors operate under extreme conditions, requiring advanced refractory solutions designed to withstand high temperatures, erosive environments, and rapid temperature changes.

The commissioning process for these reactors starts with the furnace operator specifying the operating conditions necessary to produce the desired grade of carbon black. Factors such as reactor technology, operating temperatures, geometries, fuel sources, and feedstocks are all critical in determining the optimal refractory solution.

Reactor Structure and Operation

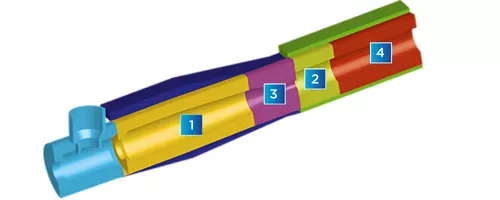

Carbon black tread reactors typically consist of several critical zones, each playing a distinct role in the production process:

1. Combustion Chamber: The initial stage where fuel combustion occurs at extremely high temperatures to generate the thermal energy needed for carbon black formation.

2. Reaction Zone: The main area where the formation of carbon black takes place through the interaction of feedstock with high-temperature gases.

3. Choke: A narrow section that helps regulate the reaction flow and maintain the necessary conditions for efficient carbon black production.

4. Quench Zone: This zone rapidly cools the reaction mixture to halt further carbon black formation and stabilize the final product.

These reactors often operate at temperatures exceeding 1500°C (2732°F) in certain zones, subjecting the reactor lining to highly erosive and corrosive environments due to the presence of hot gases and particulates.

Operating Conditions

The operating conditions of a carbon black tread reactor vary across different zones, each presenting unique challenges such as varying atmospheres (oxidizing or reducing), high gas velocities, intense chemical interactions, and frequent temperature fluctuations. Each of these factors influences the choice of refractory material and design.

Refractory Solutions

Saint-Gobain offers customized refractory solutions tailored to the specific needs of each reactor zone

- Hot Face: Uses 99% alumina bricks (AL 100, AH 199H) or zirconia bricks (ZH192) to provide resistance to high temperatures and thermal shock.

- Backup Layer: Bubble alumina castable (RI34/CA333) for insulation and additional protection.

- Hot Face: 99% alumina bricks (AL 100, AH 199) or 90% alumina bricks (Mullfrax® 202 HF) for durability against high temperatures and erosion.

- Backup Layer: Bubble alumina castable (RI34/CA333) or dense alumina castable (Supcast/CA334) for added thermal insulation and structural support.

- Hot Face: Uses high alumina bricks (AL 100, AH 199 H), Monocriram, or fused cast alumina (Jargal M) for extreme wear resistance.

- Backup Layer: Bubble alumina castable (RI34HR/CA333) to further protect against intense conditions.

- Hot Face: 90% alumina bricks (Mullfrax® 202 HF, MSR2) or high alumina bricks (AL 102 / AL102 V) to withstand rapid cooling and thermal shock.

- Backup Layer: Bubble alumina castable (RI34HR/CA333) or dense alumina castable (Supcast/CA334) for extra resilience.

Key Benefits of Advanced Refractory Solutions

- Extended Reactor Lifetime: Using advanced refractory materials can significantly extend the lifespan of carbon black tread reactors, reducing the frequency of relining and associated downtime.

- Reduced Maintenance Requirements: Enhanced durability leads to less frequent maintenance, which reduces operational costs and interruptions.

- Improved Resistance to Erosion and Corrosion: High-quality refractory materials are specifically engineered to resist the erosive and corrosive effects of hot gases and particulates.

- Enhanced Thermal Shock Resistance: The ability to withstand rapid temperature fluctuations minimizes the risk of thermal damage and ensures consistent performance.

- Increased Operational Efficiency: Optimal refractory solutions contribute to stable operating conditions, improving overall process efficiency and ensuring consistent product quality.

Carbon Black Technologies Solutions

Selecting the right refractory material is critical for the optimal performance of carbon black tread reactors. High-purity alumina and zirconia-based products are preferred for their excellent resistance to extreme temperatures, erosion, and corrosive environments. The specific grade and form of these materials (such as bricks, shapes, or castables) are chosen based on the requirements of each reactor zone and the unique challenges it presents.

By utilizing these advanced refractory solutions, carbon black manufacturers can achieve longer operational campaigns, enhance product quality, and boost overall efficiency in their tread reactors.

Saint-Gobain Performance Ceramics & Refractories works closely with furnace operators to develop and deliver refractory solutions that meet both performance and economic goals. These lining solutions are customized in terms of material form and grade to address the specific needs of each reactor zone and to optimize reactor performance.