Copper Furnace Solutions

Durable Copper Furnace Protection Built to Perform

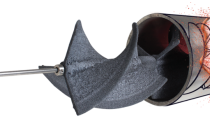

The aggressive conditions in industrial processing demand materials that can endure constant thermal, chemical, and mechanical stress. Nowhere is this more evident than in copper furnace operations, where refractory linings must perform reliably in the presence of extreme heat, corrosive slags, and abrasive environments. Sustaining performance under these conditions requires robust, high-performance copper furnace solutions, ones that can be supplied by Saint-Gobain Performance Ceramics & Refractories. Our copper furnace materials are engineered to protect critical equipment, minimise unplanned maintenance, and support operational continuity.

Adapted Solutions

Copper furnace operations expose refractories to aggressive slags, elevated temperatures, and rapid thermal cycling, all of which can degrade conventional refractory materials. In response, we have developed a third generation of silicon carbide (SiC) refractories specifically for copper furnace systems, including holding and shaft furnaces, launders, and backup linings. These advanced materials incorporate an oxy-nitride bonded system that enhances oxidation resistance and structural stability under severe operating conditions. By reducing copper penetration and maintaining integrity over time, they deliver reliable furnace protection and can help extend service intervals across both primary and secondary production environments.

Primary Copper Furnace Solutions

C104 fused cast refractories function as a high-performance copper furnace solution in flash melters and smelting zones, where contact with chemically reactive materials and mechanical abrasion is constant. Their fusion-cast microstructure provides superior resistance to corrosion and structural degradation, maintaining lining integrity under prolonged thermal stress. This makes them particularly effective for primary copper production zones, as refractory failure within these areas can lead to significant process disruption and unscheduled shutdowns.

Secondary Copper Furnace Solutions

We also provide advanced copper furnace solutions tailored to the operational demands of secondary copper production. Cryston® CU Max safeguards shaft and holding furnaces used in recycled copper processing with its oxy-nitride bonded silicon carbide composition, offering exceptional resistance to oxidation and mechanical wear. DryVibe® monolithics complement these capabilities by providing a durable, vibratable lining that simplifies installation and extends service life. Together, such solutions reduce the risks associated with thermal cycling and slag attack, delivering a proactive approach to furnace longevity.

Where Our Copper Furnace Solutions Are Used

The copper furnace solutions from Saint-Gobain Performance Ceramics & Refractories are applied across a broad range of metallurgical environments to provide reliable, high-temperature performance wherever copper is processed.

Speak to an Expert

Contact our specialists at Saint-Gobain Performance Ceramics & Refractories to find the right copper furnace protection solution for your operation.