Aluminum Annealing

Aluminum coil annealing is a secondary process found in most aluminum mills that produce coiled sheet aluminum.

Aluminum is cast and turned into thin sheets of aluminum before being wound into coils. Several coils are placed into a batch furnace containing radiant tubes and a circulating fan.

The indirect heat provided by the radiant tubes maintains critical furnace atmosphere and provides uniform temperatures, ensuring proper aluminum annealing prior to shipment or coating with zinc or other alloys.

The annealing furnace consumes a significant amount of energy and generates carbon and nitrogen oxide emissions.

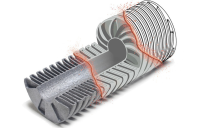

The radiant tubes’ energy usage, emissions and thermal performance can be improved through the use of high surface area heat exchangers such as HeatCor™, radiant tube inserts such as SpyroCor® and low emission devices such as NOxBuster®.

Related Products

Ceramic Radiant Tube

Discover Saint-Gobain Performance Ceramics & Refractories’ extensive range of solutions for high temperature heat treatment applications.

SpyroCor and NOxBuster Radiant Tube Insert

Discover Saint-Gobain Performance Ceramics & Refractories’ range of radiant tube inserts – ideal for improving efficiency in the furnace chamber.

HeatCor and Silit Recuperators

Discover Saint-Gobain Performance Ceramics & Refractories’ range of recuperators for integration into burner systems.

Amasic-3D Burner Nozzles

Discover Saint-Gobain Performance Ceramics & Refractories’ range of burner nozzles – ideal for guiding the flow of combustion.

PyroCor and Silit Flame Tubes

Discover Saint-Gobain Performance Ceramics & Refractories’ range of flame tubes and diffusers – ideal for guiding the flow of combustion.

Related Content

Total Burner Solution for Energy Efficiency and Carbon Reduction

Discover Saint-Gobain Performance Ceramics & Refractories’ extensive range of total burner solutions for industrial heating applications.

Single Ended Radiant Tubes

Discover Saint-Gobain Performance Ceramics & Refractories’ extensive range of solutions for high temperature heat treatment applications.

U-TUBE

Discover Saint-Gobain Performance Ceramics & Refractories’ solutions for high temperature heat treatment applications in U-tube combustion systems.

W-TUBE

Discover Saint-Gobain Performance Ceramics & Refractories’ solutions for high temperature heat treatment applications in W-tube combustion systems.