Industrial Separation Processes

Purity and reliability are paramount in industrial applications such as powders separation, and chemicals recovery, as well as food and beverage and biotechnology processes such as clarification and bacteria removal. Crystar® silicon carbide microfiltration can support the manufacturing of high value products with consistent retention cut-offs and long lifetime with very effective operating conditions for filtration and cleaning cycles.

Ceramic microfiltration (MF) membranes

Ceramic microfiltration (MF) membranes have been used for some decades on specific applications like dairy processing or pharmaceutical broth filtration. Now the technology is also finding additional pervasive uses in various industrial processes and life science spaces. Crystar® ceramic membranes have been engineered to enhance the performance of a range of microfiltration applications, with enhanced corrosion and thermal shock resistances, improved flux, and outstanding retention of extremely small particles.

The benefits of ceramic microfiltration membranes vary depending on the application, but they all translate to enhanced productivity by enabling longer periods of filter operation and reduced downtime for mandatory maintenance and cleaning operations. Saint-Gobain’s Crystar products take end users to a step further in terms of productivity, thanks to more efficient and faster cleaning processes made possible by the outstanding chemical and thermal shock resistance of recrystallized silicon carbide. Crystar® FT membranes are available in both cross flow and dead-end configurations, enabling installation in a range of process and life science facilities.

Related Content

Filtration

Crystar® Filtration Technology provides highly efficient microfiltration with consistent retention, low energy consumption and excellent filtrate quality...

Chemical Recovery

Chemical recovery stands to benefit from ceramic microfiltration due to the unmatched corrosion resistance of Crystar® products.

Powder manufacturing & Recovery

Crystar® FT is a suitable alternative to slurry evaporation, or an effective pre-treatment prior to it, in a variety of inorganic and organic powder...

Drinking Water Production

Crystar® liquid filtration technology offers excellent levels of efficiency in terms of microorganism retention and particulate removal, combined with high...

Wastewater Treatment

Crystar® FT is poised to interrupt this cycle of consumption and pollution by providing a cost-effective solution for the filtration of challenging and...

Beer Clarification

Provide a high productivity and cost-effective solution to reduce haze in the finished beer in order to ensure its visual quality and contribute to its...

Wine Clarification

Crossflow microfiltration is a key step to ensure the sensorial properties and stability of wines, which are of utmost importance to the product value.

Coconut Water Clarification

Coconut water clarification is a crucial part of the production process, due to the high turbidity and presence of microorganisms such as C. botulinum...

Related Products

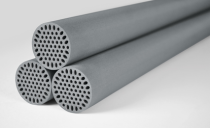

Crystar Crossflow

Crystar® FT’s proprietary crossflow technology uses multi-layered membranes of high purity recrystallized silicon carbide (R-SiC) supported by the most...

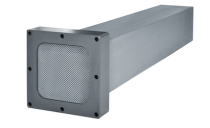

Crystar Deadend

Crystar® FT’s proprietary dead-end technology uses multi-layered membranes of recrystallized silicon carbide (R-SiC) carried by a unique honeycomb monolith...