Food & Grains

Abrasion Resistant Ceramic Linings for Bulk Material Handling Systems

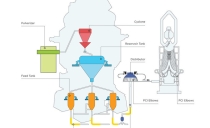

Saint-Gobain Performance Ceramics & Refractories’ proven ceramic lining solutions are ideal for applications involving bulk grains in spouting, bins, or hoppers – from mine to rail or ship loadout.

A range of specialist solutions is also available to accommodate fertilizer handling, including potash and phosphates.

FAQ

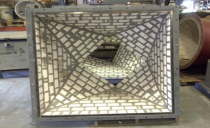

What is the most suitable lining for handling soybeans in spouting?

Durafrax® has demonstrated proven performance and cost-effectiveness for over 30 years. When installed in conjunction with the WearPak 750 adhesive, Durafrax® can ensure FDA approval, extended service life and minimal maintenance requirements.

What is the most suitable solution for applications handling abrasive and corrosive phosphoric acid?

Saint-Gobain Performance Ceramics & Refractories’ ceramics are extremely resistant to acids and bases, and specific lining systems can accommodate phosphoric acid.

Each individual application is evaluated by teams of experienced engineers, ensuring that any solution recommended is ideal for the application’s acid concentration and temperature.

Related Equipment

Crushing, Pulverizing, and Grinding Components

Discover Saint-Gobain Performance Ceramics & Refractories’ extensive range of cost-effective wear resistance solutions for crushing, pulverizing and...

Separation and Screening Components

Discover Saint-Gobain Performance Ceramics & Refractories’ extensive range of cost-effective wear resistance solutions for separation and screening...

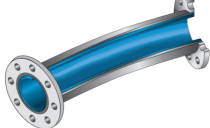

Piping Components

Discover Saint-Gobain Performance Ceramics & Refractories’ extensive range of cost-effective wear resistance solutions for piping components.

Belt Conveyor Components

Discover Saint-Gobain Performance Ceramics & Refractories’ extensive range of cost-effective wear resistance solutions for belt conveyor components.