Water & Waste Water

Sustainability is increasingly important in every major industrial sector, with a large focus on the recovery of waste water and production of high quality process water. Additionally, increasing needs for drinking water availability, safety, and quality also calls for the development of better water treatment technologies. Crystar® ceramic microfiltration is ideal for recycling difficult industrial waste waters, for instance as a polishing step to prepare water with consistent and reliable quality prior to reverse osmosis or nanofiltration processes. Crystar membranes also provides an excellent alternative in drinking water production plants, thanks to excellent permeate qualities, high water recovery rates, low pressure operation and unmatched compactness.

Improve Water Savings, Water Security, and Water Safety

Every day, 2 million tons of sewage, industrial, and agricultural waste are discharged into the world’s water. Sustainability is increasingly important for global infrastructures attempting to meet growing demands without commensurately increasing their environmental footprint. In the water and waste water sector, this translates as a desire to improve water savings, water security, and water safety. The scarcity of water has become a significant issue for the developed and the developing world. Indeed, a water gap of 40% is predicted by 2030 if no actions are taken to recover and reuse water.

Crystar® ceramic membranes were engineered for cutting-edge water microfiltration that provides a cost-effective method for the production of drinking water and the recycling of waste water. This innovative water microfiltration technology is comprised of multiple layers of recrystallized silicon carbide, with high filtration areas and improved filtration fluxes. Crystar® ceramic membranes have been engineered for both cross flow and dead-end water microfiltration, with an extensive range of potential applications in the water and waste water sector.

Related Products

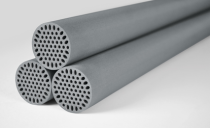

Crystar Crossflow

Crystar® FT’s proprietary crossflow technology uses multi-layered membranes of high purity recrystallized silicon carbide (R-SiC) supported by the most...

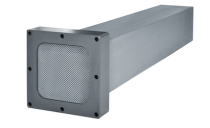

Crystar Deadend

Crystar® FT’s proprietary dead-end technology uses multi-layered membranes of recrystallized silicon carbide (R-SiC) carried by a unique honeycomb monolith...

Related Content

Drinking Water Production

Crystar® liquid filtration technology offers excellent levels of efficiency in terms of microorganism retention and particulate removal, combined with high...

Wastewater Treatment

Crystar® FT is poised to interrupt this cycle of consumption and pollution by providing a cost-effective solution for the filtration of challenging and...

Oil & Gas Produced Water

Crystar® FT introduces an innovative method for ethical oil and gas wastewater disposal, or for its efficient reuse, for instance as water re-injection.

Crystar Ceramic Membrane Filters for water and wastewater treatment

Crystar® ceramic membrane filters are high-performance filters developed to tackle the most difficult liquid microfiltration applications