Life Sciences

High-Quality Ceramics for various applications

Saint-Gobain Performance Ceramics & Refractories produces a range of adaptable ceramic solutions for various applications in the life science industry. Through years of experience, our R&D centre has developed unique engineered ceramics that meet the requirements of the Life Sciences markets.

Discover all the services and products we provide:

New material capacities and improved component performance have enhanced the way biotechnological processes work at industrial scales. Fermentation is one of the principal procedures conducted in biotechnology facilities. This process is multi-disciplinary and is applicable in sectors as diverse as the food and beverage, pharmaceutical, and chemical industries. Crystar® FT has supported the innovative trajectory of fermentation processes by enhancing the performance of fermentation broth and cell harvesting clarification, where a desirable biomass is separated from the intermediate broth.

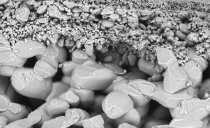

Fermentation broth microfiltration improves the quality of biomass products with improved material yields due to the unmatched performance of advanced recrystallized-silicon carbide (R-SiC) filtration membranes. Crystar® FT can resist aggressive media with leading filtrate flux capacities for demanding slurries and corrosive agents. The sharp selectivity of Crystar FT offers the best pre-filtration option in the recovery processes of proteins, active pharmaceutical compounds, and other valuable nano products.

Crystar® microfiltration is also poised to improve the performance of conventional microorganism removal and yeast separation in biochemical reactions. The negatively-charged membrane surface and well-controlled pore sizes, allow for the optimization of the filtration of organic particulates from liquid feeds, enabling facilities to effectively eliminate contaminants from various filtrates.

The inherent benefits of Crystar® FT yields optimal benefits in biotechnology applications. Contact us if you would like more information on how to optimize your microfiltration process using recrystallized-silicon carbide ceramic membranes.

Refractory products from Saint-Gobain Performance Ceramics & Refractories confidently meet and exceed the stringent chemical and physical labware requirements in life sciences applications, including:

- Ignition

- Weighing

- Melting

- Incineration

- Combustion

- Extraction

- Filtering

Saint-Gobain Performance Ceramics & Refractories is the industry leader in ceramic refractory production and engineering. The company’s products are ideal for conventional and specialist laboratory operations. Outstanding shaping capabilities and unparalleled materials expertise allows customized solutions to be developed for any application. Available labware products include:

- Combustion boats with and without handles

- Dishes

- Thimbles

- Filter discs and cones

- Crucibles

- Covers

FAQ

Does Saint-Gobain Performance Ceramics & Refractories’ labware remain chemically resistant and stable in contact with reagents and solvents at high temperatures?

Yes. Labware made from Alundum® 99% pure aluminum oxide provides outstanding stability and chemical inertness at temperatures up to 1,450 °C. Zirnorite® zircon labware may be used at temperatures up to 1,590 °C in applications where thermal shock resistance and speed of determination are essential. Alundum® labware has high thermal conductivity, excellent electrical resistance at high temperatures, good mechanical strength, and can be used many times before requiring replacement.

How to achieve M.O.R.E. with Crystar® FT?

Our Crystar® technology is based on a proprietary arrangement of recrystallized silicon carbide (SiC) layers, featuring a naturally negative surface charge like most microorganisms and natural organic matter. Combined with a well-controlled and engineered pore size range of 0.25 – 4.0μm, this enables an excellent trade-off between permeate flux and retention of microorganisms.

This Micro Organism Retention Efficiency (M.O.R.E.) has been demonstrated without the use of coagulants by measurements performed by renowned laboratories in Europe and the USA. (Measurements performed at Fresenius Institute (Germany), Dresden University (Germany), Firmus (France), University of North Carolina (USA).

Related Content

Filtration

Crystar® Filtration Technology provides highly efficient microfiltration with consistent retention, low energy consumption and excellent filtrate quality...

Crystar Filtration Technology

Effective removal of microorganisms can be uniquely challenging and often requires redundancy in the fluid treatment process.

Specialty Ceramics

Saint-Gobain Performance Ceramics & Refractories’ extensive range of specialty ceramic products – ideal for use in the harsh environments typical in broad...

Ceramic Labware

Made from high-purity Alundum® alumina, labware products stand up to thermal shocks and the harsh chemicals commonly encountered in laboratories. Product...

Chemical Recovery

Chemical recovery stands to benefit from ceramic microfiltration due to the unmatched corrosion resistance of Crystar® products.

Powder manufacturing & Recovery

Crystar® FT is a suitable alternative to slurry evaporation, or an effective pre-treatment prior to it, in a variety of inorganic and organic powder...

Related Products

Alundum Labware

Discover Saint-Gobain Performance Ceramics & Refractories’ extensive range of ceramic products for laboratory operations and analytical instruments.

Zirnorite Refractory Shape

Discover Saint-Gobain Performance Ceramics & Refractories’ range of Zirnorite® zirconia refractory products - extreme high-temperature stability and...

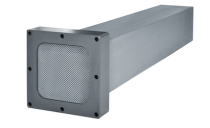

Crystar Deadend

Crystar® FT’s proprietary dead-end technology uses multi-layered membranes of recrystallized silicon carbide (R-SiC) carried by a unique honeycomb monolith...