Primary Copper

Saint-Gobain Performance Ceramics & Refractories has introduced a third generation of silicon carbide (SiC) refractories designed to effectively protect copper furnaces.

Dedicated R&D teams have developed high performance materials that offer an industry-leading service life. In the field, experienced engineers apply their design expertise to deliver refractory systems that enhance furnace performance, reliability and service life.

Solution By Equipment

Click on your equipment to find more:

- Flash Melter

Flash Furnace for Primary Copper Production

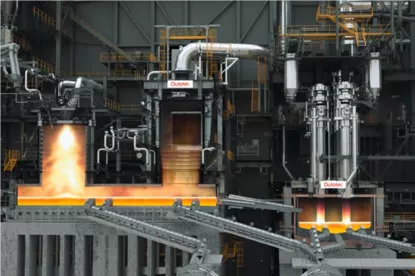

The flash furnace relies on specialized refractories to deliver cost-effective performance, regardless of whether it is smelting copper, nickel or lead.

Saint-Gobain Performance Ceramics & Refractories’ C104 material enhances the furnace's resistance to aggressive slag formed by the smelting process. C104 fused cast refractories are ideal for use in critical, high wear areas of the flash furnace. Its remarkable stability in the harshest chemical environments allows furnace linings to last longer, ensuring greater total refractory utilization.