Heat Treatment

Saint-Gobain Performance Ceramics & Refractories has been designing and manufacturing high performance refractories for demanding atmosphere furnaces for over 70 years. Our team of application engineers, material scientists and design engineers understand the conditions in atmosphere furnaces and can help you choose the correct material for your application.

Benefit from these advantages:

• Custom engineering to customer specifications

• Consistently high-quality manufacturing

• Extensive worldwide capacity

• Robust export compliance

• Manufacturing locations on multiple continents

• Global R&D resources

Solution By Application

Click on your application to find more:

- Hydrogen Atmosphere

- Hydrogen-Nitrogen Atmosphere

Hydrogen Atmosphere

|

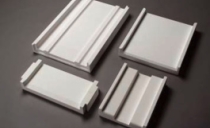

Alundum® 99 furnace refractory should be specified in hydrogen atmosphere furnaces that operate from 1,205 - 1,870°C (2,200 - 3,400°F). This ultra-low silica content refractory will minimize or eliminate the contamination and degradation that results from the reduction and re-oxidation of silica, soda and potassium found in many refractory shapes. |