Ironmaking

General Areas Served

Blast furnace

Challenging conditions affect every area of a conventional blast furnace. For the hearth pad and hearth wall, tuyere belt, bosh and belly, lower and upper stack the lining of these areas has to deal with elements such as molten iron, corrosive vapors and abrasion from the solid burden. Raw materials entering through the throat may be a source of wear and tear, while coarse particles and carbon monoxide-rich gases produced as by-products can cause problems from the bottom up.

At Saint-Gobain Performance Ceramics & Refractories, we develop advanced, sustainable solutions for every stage of ironmaking. Our Coranit® Al and SlagR ceramic cup technology reduces CO₂ emissions and extends furnace life. We offer castable and shotcrete options for various furnace repairs, including the hearth and stack areas. With a full portfolio of engineered refractories, we help blast furnace operators reduce the number of repairs, heat losses, fuel rates, costs and meet today’s environmental standards.

Solution By Application

Click on your application to find more:

- Blast Furnaces Refractories

- Blast Furnace Repairs

- Tap Hole Clay

- Torpedo Car (Torpedo Ladle)

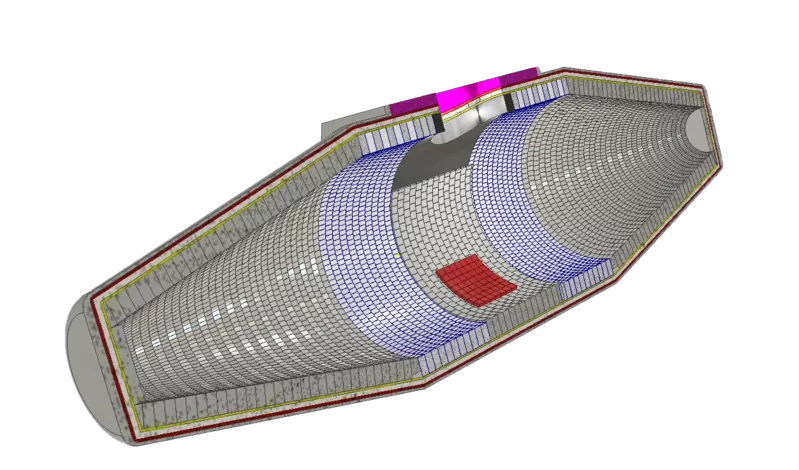

Torpedo Car (Torpedo Ladle)

High Performance and Operational Safety

While torpedo cars – also referred to as torpelo ladles – typically serve as transfer containers, these key pieces of equipment are frequently employed in liquid metal treatments such as desulfurization and desiliconization.

These processes involve higher temperatures, higher metal/slag turbulence, and greater chemical attack, requiring high-quality refractory linings.

Saint-Gobain Performance Ceramics & Refractories’ refractory linings have been supplied to customers in Europe, America and Asia. Customized, balanced lining designs are also available to address the specific type of wear prevalent in different torpedo ladle areas.

Features and Benefits

| Products | Characteristics | Applications | Benefits |

| Bricks | Al2O3-SiC-C based, High oxidation and corrosion resistance | Working lining | Higher campaign life, even when subjected to desulfurization treatment or high thermal shock |

| Castable | High mechanical resistance | Mouth | Reduced repair requirements |

| Shotcrete | High performance | Repair | Al2O3-SiC-C based with high adhesion, minimal rebound losses, and exceptional wear resistance |

| Gunning Mix | Al2O3 or Al2O3 SiC based, High strength | Repair | Specialized design for hot application and fast repair |

FAQ

Why do Saint-Gobain Performance Ceramics & Refractories’ ACS bricks offer such high thermal shock resistance?

ACS bricks’ thermal shock resistance is due to a combination of carefully selected high quality raw materials designed to ensure the perfect thermal balance; and an engineered structure with a high degree of stress attenuation. This combination allows equipment to move through thermal cycles while suffering very little damage to its inner structure, ensuring a long service life.