Primary Aluminium

In the demanding environment of primary aluminum production, refractory materials must deliver exceptional thermal performance and durability. Saint-Gobain’s solutions are specifically designed to enhance reduction cell efficiency, increase operational life, and withstand the harshest chemical and thermal conditions.

Backed by decades of innovation, our materials support the next generation of high-performance aluminum smelting operations.

- Primary Aluminium

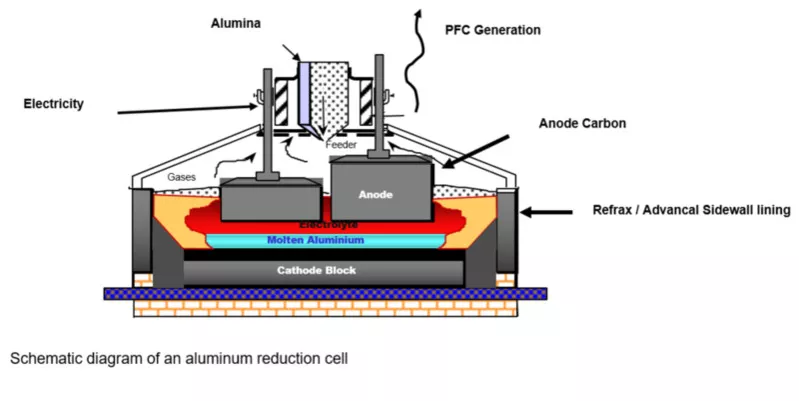

Al2O3 + Na3AlF6+ electricity = aluminum + CO2+ fluorides

Nitride bonded SiC refractories, Advancal® and Refrax® ARC, have become the reference material for the sidewall lining of modern aluminum reduction cells. Advancal®, the latest aluminium reduction cell material from Saint-Gobain, offers outstanding corrosion, chemical and oxidation resistance.

Silicon Nitride bonded SiC refractories provide extended service life through improved oxidation and corrosion resistance.

Thinner sidewalls can be achieved with Advancal® aluminium reduction cells maximize heat flow characteristics through the wall to improve reduction cell performance.

This is achieved through:

- Larger bath volume which allows for larger anode

- Increased power due to the thinner, more thermally conductive SiC sidewalls and less electrical conductivity of the wall

- Superior oxidation resistance

- Excellent erosion and corrosion resistance when the sidewall is directly exposed to the Cryolithic bath or to the molten metal flow as it occurs in the case of Anode effects

Saint-Gobain leads the industry in the development of innovative aluminium reduction cell materials.