Secondary Aluminum

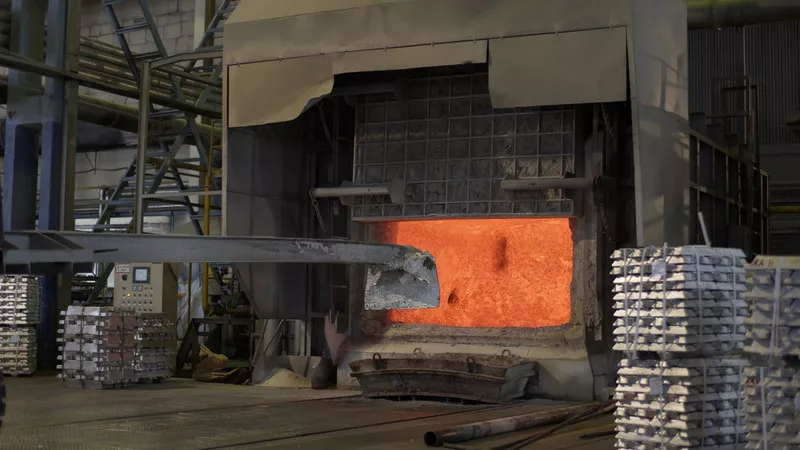

Melting furnaces are used to melt scrap or recycled aluminium, requiring a high heat input since the roof temperature can exceed 1,100°C. Holding furnaces receive molten metal from either the primary reduction potlines or from the melting furnaces. They operate at lower temperatures. Alkali chlorides and fluorides are often used as flux, to avoid bath oxidation and to help remove impurities in melting furnaces. These salts are very aggressive to the refractories.

Molten aluminium is able to reduce many oxides found in the refractory linings, such as SiO2, Fe2O3, TiO2 to their metallic state. The by-product of this reaction is corundum. The accumulation of corundum on the refractory lining presents a major problem in melting furnaces.

A combination of oxy-nitride bonded SiC bricks (Cryston® CN190 and CN806 oxy-nitride bonded SiCs) and low porosity, chemically bonded Alfrax® PB110 alumina bricks offers an optimal cost-performance compromise for ramp and hearth lining. Saint-Gobain also provides nitride bonded SiC Refrax® 20 and Cast Refrax® tap out blocks, throat inserts and stopper rods.

Solution By Equipment

Click on your equipment to find more:

Holding & Melting Furnaces

The holding furnace is an essential part of the continuous casting process. Its highly specialized design requires the use of custom refractory shapes such as inlet and outlet ports, skim and vent doors and burners.

The hot face material is composed of Saint-Gobain Performance Ceramics & Refractories’ Cryston® CU bonded SiC, ensuring extended service life.

Documents

Want to know more ?

Contact our experts now to explore the development opportunities that await you. Click the button below to fill out the form, and we will be delighted to accompany you on your journey.