Blast furnace

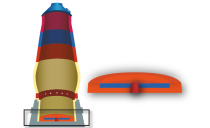

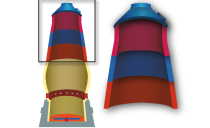

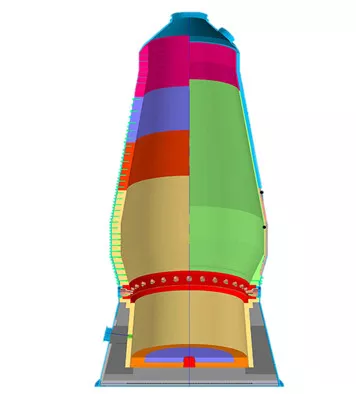

Challenging conditions affect every area of a conventional blast furnace. For the hearth pad and hearth wall, tuyere belt, bosh and belly, lower and upper stack the lining of these areas has to deal with elements such as molten iron, corrosive vapors and abrasion from the solid burden. Raw materials entering through the throat may be a source of wear and tear, while coarse particles and carbon monoxide-rich gases produced as by-products can cause problems from the bottom up.

At Saint-Gobain Performance Ceramics & Refractories, we develop advanced, sustainable solutions for every stage of ironmaking. Our Coranit® Al and SlagR ceramic cup technology reduces CO₂ emissions and extends furnace life. We offer castable and shotcrete options for various furnace repairs, including the hearth and stack areas. With a full portfolio of engineered refractories, we help blast furnace operators reduce the number of repairs, heat losses, fuel rates, costs and meet today’s environmental standards.

Solution By Application

Click on your application to find more:

- Blast Furnaces Refractories

- Blast Furnace Repairs

- Tap Hole Clay

- Torpedo Car (Torpedo Ladle)

Blast Furnaces Refractories

Refractory Solutions for Increased Blast Furnace Service Life

Conventional coke blast furnaces are still essential to large-scale iron making processes. However, these operations are extremely demanding. The intense thermal, mechanical, and chemical conditions required to reduce iron ore place significant stress on refractory linings. Blast furnaces are built to last for more than 15 years. Over time, however, the extreme thermal, mechanical, and chemical stresses can take a serious toll on refractory linings. That’s why choosing the right refractory materials is critical to maintaining performance and reliability throughout the furnace’s life.

We deliver high-performance refractory solutions for each area of the blast furnace designed to withstand the most demanding conditions. The requirements for long service life combined with wear and tear have been made more challenging by new requirements such as carbon dioxide (CO2) reduction and usage of Syngas and hydrogen (H2) injection.

Saint-Gobain Performance Ceramics & Refractories has over 50 years of experience in blast furnace refractory design. We are continually adapting our product portfolio to exceed the needs of our valued partners. With CO2 reduction and green steel objectives becoming more prevalent, it is our goal to make blast furnace operation easier and cleaner than ever.

Conventional coke and charcoal blast furnace require specific types of refractories to ensure smooth operation.

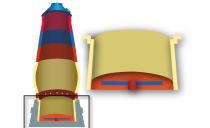

We provide a comprehensive range of products for conventional coke blast furnaces, many of which have been customized according to customers’ requirements and operating conditions. Since 1982, we have pioneered novel ceramic cup technology for blast furnace hearths and are now offering the third generation of our industry-leading Coranit® SlagR Ceramic Cup technology. The previous generation extended hearth wall life by as much as 10 years, the Coranit SlagR ceramic cup now adds another 2-3 years.

Main benefits of the Ceramic Cup are:

- Lower energy and coke consumption

- Reduction of CO2 emissions

- Quick pay-back within 3 years

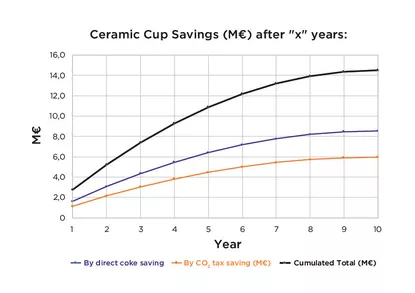

Developing technical solutions and achieving operational improvements is key to respond effectively to the rising cost of CO₂ emissions.

Achieving CO2 & Coke Reduction

CO₂ taxes are increasing significantly, and importing raw materials in certain regions may soon add further costs that could challenge the long-term stability of iron and steel production.

But at Saint-Gobain, we believe there is enormous financial value to be found within more sustainable practices. Reducing CO2 emissions and coke consumption using ceramic cup technology and additional high-performance refractory linings and hearth products is vital for this objective. Our solutions allow end-users to reduce coke consumption with no loss of throughput or yield. The immediate cost saving is achieved by lowering the coke and energy consumption and the reduction of CO2 emissions, leading to substantial cost savings therein, especially in Europe where the CO2 certificate trading is in place.

Documents

FAQ

How can Ceramic Cup help to save CO2 emissions and lower coke/energy consumption?

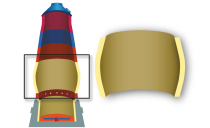

Saint-Gobain’s third generation Ceramic Cup quality Coranit SlagR has improved resistance to iron, slag alkali corrosion and wears very gradually over the lifetime of the hearth.

With its insulating effect compared to a pure carbon hearth the Ceramic Cup reduces the coke consumption and the CO2 emission at the same time.

With the CO2 certificate trading already existing in Europe and for other regions/countries to come (e.g. China*) the money saving effect will become a more and more important factor.

Total CO2 Savings 65KT Total Coke Savings 20KT

Graph: Case study calculated on an existing blast furnace with ceramic cup (hearth diameter 11m)

How can the Ceramic Cup in Coranit SlagR extend the hearth wall lifetime?

The Coranit® Ceramic Cups wear very gradually over the lifetime of the hearth and is the first life of the hearth. After it is worn second hearth life with carbon wall lining continues.

The second generation Ceramic Cup quality Coranit AL with its 34 references over the last 20 years was proven to last >10 years.

Saint-Gobain’s third generation Ceramic Cup quality Coranit® SlagR has improved resistance to iron, slag alkali corrosion and is expected to last an additional two - three years compared to its predecessor Coranit® AL.

How was the Coranit Ceramic Cup developed?

Two sites in Germany - Thyssen's Hamborn and Ruhrort sites - first installed the Ceramic Cup technology in 1984. The first generation of Ceramic Cup was based on chrome-alumina in the form of large precast Monochromcor® blocks, while the second generation was corundum in the form of large precast Mono Coral® blocks. These blocks helped to reduce hearth stresses while addressing issues with chrome VI. The third generation of Ceramic Cup products was developed from pressed SiAlON bonded corundum Coranit bricks and first installed in 1993. This further reduced stresses while offering improved iron erosion resistance. First installed in 2020, Coranit SlagR offers excellent resistance to molten iron and slag and unprecedented hearth lining protection.

What are the benefits of working with Saint-Gobain Performance Ceramics & Refractories?

Saint-Gobain Performance Ceramics & Refractories offers a robust combination of continuous development and provision of the highest quality customized refractory product solutions, full design and engineering services, supervision and ongoing support – a complete, reliable and cost-effective service through a furnace's entire service life.