A New Spin on Zinc Melting Furnaces

For over half a century, wire galvanizers have relied on immersion tube furnaces for fast and efficient melting performance. Over that time, gas burner technology has advanced steadily, but the same has not been true of immersion tubes, which play a critical role in transferring the burner’s heat to the metal.

Saint-Gobain Performance Ceramics & Refractories is closing this technology gap with the introduction of their enhanced SpyroCor® flame diffuser insert for immersion tube furnaces.

“Wire galvanizers will benefit in particular,” said Julio Spadaccia, North American Non-Ferrous Sales Manager for Saint-Gobain Performance Ceramics and Refractories (SG PCR). “By transferring more heat from the burner to the metal, customers can melt faster and even push the furnace to produce more wire,” adding, “and the galvanizing market needs more capacity!”

“Wire galvanizers will benefit in particular,” said Julio Spadaccia, North American Non-Ferrous Sales Manager for Saint-Gobain Performance Ceramics and Refractories (SG PCR). “By transferring more heat from the burner to the metal, customers can melt faster and even push the furnace to produce more wire,” adding, “and the galvanizing market needs more capacity!”

Customers can also count on energy savings, according to Tom Briselden, inventor of the AmaSiC-3D® platform and current Global New Business Director for SG PCR. “When you improve the efficiency of your burners, you can dial back the fuel without cooling down the furnace. SpyroCor® inserts allow that. So, what it means for customers is a lower gas bill every month, and over the course of a year it represents a healthy cost savings.”

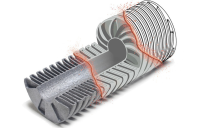

The SpyroCor® flame diffuser insert features two innovative and performance-enhancing concepts:

- The “twisted tape” design for improved convective heat transfer;

- The AmaSiC-3D™ silicon carbide material for increased radiant heat transfer.

Related Content

Product

Amasic-3D Burner Nozzles

Discover Saint-Gobain Performance Ceramics & Refractories’ range of burner nozzles – ideal for guiding the flow of combustion.

Product

SpyroCor and NOxBuster Radiant Tube Insert

Discover Saint-Gobain Performance Ceramics & Refractories’ range of radiant tube inserts – ideal for improving efficiency in the furnace chamber.