Filtration

Saint-Gobain Performance Ceramics & Refractories have been providing unique and high added value silicon carbide-based solutions for decades, including the first-to-market recrystallized silicon carbide (R-SiC) product. This outstanding ceramic forms the basis of our Crystar® filtration technology.

Crystar® FT is designed for liquid and air purity, security, and sustainability. The demands of filtration have changed dramatically over the years, as a growing global population forces industries to adopt more demanding processing capabilities to satisfy the needs of global sustainability efforts.

Saint-Gobain designs, manufactures and distributes materials and solutions which are key ingredients in the well being of each of us and the future of all. They provide comfort, performance and safety while addressing the challenges of sustainable construction, resource efficiency and climate change.

With Crystar® FT membranes and filters, Saint-Gobain is committed to improving the sustainability of sectors as diverse as water/wastewater, industrial processes & life sciences, and recreational water, with new and innovative products.

We aim to make sustainability a driving force for every liquid filtration and air purification sector. Crystar® FT technology provides microfiltration of leading efficiency, with consistent retention, excellent filtrate quality at high fluxes, and operation with low consumption of energy, water and chemicals.

Swimming pool

An efficient and Environmentally Friendly Filtration Technology

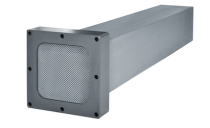

Crystar® ceramic membranes filter pool water through a unique honeycomb dead-end architecture of parallel channels with stable and well-engineered porous microstructure. This specific geometry features a high filtration area in compact filtration membrane elements (16 m2 in a filtration membrane element of 149 x 149 x 1000 mm). Each filtration element provides a filtration capacity in the range of 5 to 20 m3/h depending on the membrane pore size and pool usage. The high permeability of recrystallized silicon carbide allows for low pressure operation, typically in the range of 0.25 to 0.75 bar (2.5 to 7.5 meters of water column). As a results, excellent water quality can be obtained at low energy consumption.

The honeycomb geometry also allows for fast backwash cycles with low water consumption. Only 15-80 liters are needed during a backflush of 3 to 5 seconds to clean a Crystar® membrane. Compared to sand filers, water usage for backwash operations can hence be decreased by as much as 70%. As a consequence, the costs of water renewal heating and chemical treatment can also be significantly lowered. The fast and frequent backwashing of the filtration membranes also contributes to the reduction of chloramines and trihalomethanes, reducing skin and eye irritation as well as the risk of diseases such as asthma and allergy due to the long-term exposure to these chlorinated compounds.

A Physical Barrier Against Micro-Organisms

Last but not least, another critical advantage of ceramic microfiltration technology over established sand filters is the improved retention of micro-organisms. These pathogens, such as Cryptosporidium and Giardia, may be resistant to chlorine and can cause harm to swimmers. Moreover, free chlorine in pool water may react with substances such as skin microbes and sweat to produce chloramines, which create unpleasant odors and cause irritation of the eyes, skin and respiratory system.

Numerous swimming pools have failed routine safety inspections due to inefficient and outdated pool filtration systems, resulting in expensive pool closures. There have also been a number of reported instances of lifeguards and employees with respiratory diseases linked to consistent exposure to indoor pool environments.

Filtration of various harmful microorganisms has been measured using Crystar® ceramic membranes with demonstrable results. Cryptosporidium removal is ensured with a proven efficiency of over 99.996% using Saint Gobain’s HiFlo ceramic membrane, which has also been tested for legionella removal with a success rate of up to 99.96%, without the use of flocculants. So Crystar® membranes brings a significant contribution to water disinfection, making the pool water safer and allowing the reduction of chlorine usage.