Hexoloy® SA Sintered Silicon Carbide Material

Material Properties

Hexoloy® SA SiC is a pressure-less, sintered form of alpha silicon carbide, with a density greater than 98% theoretical. It has a very fine grain structure (4-10 microns) and contains no free silicon.

Hexoloy® SA SiC‘s chemical purity and engineered microstructure ensures excellent resistance to a wide range of chemicals. It is also highly resistant to wear from rotation and sliding forces, while offering excellent erosion resistance in abrasive blasting applications and high temperature stability in oxidizing and reducing environments.

How Saint-Gobain Performance Ceramics & Refractories manufactures its precision engineered Hexoloy® sintered silicon carbide products?

Saint-Gobain Performance Ceramics & Refractories pioneered the technology to manufacture a pressureless sintered silicon carbide material - Hexoloy® - in the late 1970s.

Forming Options

Economical forming is determined by shape, quantity volume and tolerances of the final part.

Dry pressing to size is the most economical forming method for volumes of 300 pieces or more, which helps justify the initial expense of tooling designed specifically for each part.

Isostatic pressing is best suited to low volumes and prototype items.

Pre-Sinter (Green) Machining

Machining in the pre-sintered, or green, state is desirable because it allows manufacturing of complex finished shapes without expensive grinding of sintered material.

Green machining is accomplished using conventional processes. Stock removal can be accomplished 15 times faster in the green state than in the sintered state.

Green machining provides parts to tolerances of 0.5% to 1.0% of their final dimensions. Typical green machined surface finishes range between 32 and 64 µin.

Grinding and Finishing

Precision grinding capabilities have been developed to meet the exacting specification requirements required by the automotive, aerospace and nuclear industries.

Saint-Gobain Performance Ceramics & Refractories has the expertise to grind to close tolerances on most shapes (.0005").

Typical ground parts hold finishes of 16 µin or better. When surface finishes are critical in improving friction and wear performance, finishing operations can improve surfaces up to 4 µin providing surface flatness to one helium light band.

Quality Assurance

Saint-Gobain Performance Ceramics & Refractories maintains the highest level of quality by leveraging state-of-the-art, non-destructive evaluation equipment for final quality inspections of internal structures.

These techniques include bulk and surface wave ultrasonics, fluorescent dye penetrant, radiography, acoustic emission, and photomicrography.

Hexoloy® Grade Specifications

| Property | Units | Typical Values |

| Composition* | SiC | |

| Grain Size | µm | 44,473 |

| Density | g / cm3 | 3.15 |

| Hardness (Knoop)** | kg / mm2 | 2,800 |

| Flexural Strength 4pt @ RT*** | MPa | 380 |

| x103 lb / in2 | 55 | |

| Flexural Strength 3 pt @ RT*** | MPa | 550 |

| x103 lb / in2 | 80 | |

| Modulus of Elasticity @ RT | MPa | 410 |

| x106 lb / in2 | 59 | |

| Weibull Modulus (2 parameter) | 8 | |

| Poisson Ratio | 0.14 | |

| Fracture Toughness @ RT | MPa x m1/2 | 4.60 |

| Double Torsion & SENB | x103 lb / in2 x in1/2 | 4.20 |

| Coefficient of Thermal Expansion | x10-6 mm / mmK | 4.02 |

| RT to 700°C | x10-6 in / in °F | 2.20 |

| Maximum Service Temp. | °C | 1,900 |

| Air | °F | 3,450 |

| Mean Specific Heat @ RT | J / gmK | 0.67 |

| Thermal Conductivity @ RT | W / mK | 125.6 |

| Btu / ft h °F | 72.6 | |

| @ 200° C | W / mK | 102.6 |

| Btu / ft h °F | 59.3 | |

| @ 400° C | w / m°K | 77.5 |

| Btu / ft h°F | 44.8 | |

| Permeability @ RT to 1000°C | Impervious to gases over 31 MPa | |

| Electrical Resistivity @ RT**** | ohm-cm | 102 - 1011 |

| @ 1000°C | ohm-cm | 0.01 - 0.2 |

| Emissivity | 0.9 |

Hexoloy® Enhanced SA SiC exhibits reduced microporosity, increased flexural strength and a higher Weibull modulus.

These factors make it ideal for critical applications involving:

- High stress loads

- High rotational speeds

- Improved wear properties

Related Products

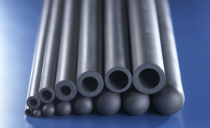

Hexoloy Seal Tubes

Hexoloy® SA sintered silicon carbide seal tubes are available in a wide range of OD and ID combinations. Seal tubes are unground and sold with “as-fired”...

Hexoloy® SE Thermocouple Protection Tube

Discover Saint-Gobain Performance Ceramics & Refractories’ range of products for thermocouple sensor protection.

Hexoloy SiC Process Tubes

Discover Saint-Gobain Performance Ceramics & Refractories’ range of process tubes for high temperature processes.

Ceramic Cyclone Linings

Discover Saint-Gobain Performance Ceramics & Refractories’ extensive range of ceramic cyclone linings.

Ceramic Chute, Bin and Hopper Linings

Discover Saint-Gobain Performance Ceramics & Refractories’ extensive range of ceramic chute, bin, and hopper linings.

Elbows, Pipes and Fittings Linings

Discover Saint-Gobain Performance Ceramics & Refractories’ extensive range of cost-effective wear resistance solutions – able to extend the service life of...

HAMMERfrax Wear Resistant Lining

HAMMERfrax® is a proprietary patented reaction bonded silicon carbide with noticeably better erosion/wear performance.

Ceramic Ductwork Linings

Discover Saint-Gobain Performance Ceramics & Refractories’ extensive range of ceramic ductwork linings.