HeatKing™ Refractories for Steel Coreless Induction Furnace

Saint-Gobain's HeatKing™ product line presents an innovative monolithic lining system solution for steel melting in coreless induction furnaces with a unique structure to insure best performance in terms of quality and cost per unit mass of steel produced, productivity, safety, energy efficiency and sustainability. The HeatKing product range takes into account the special interaction and operations in melting of steel in coreless induction furnaces and helps our customers to run their operations more efficiently.

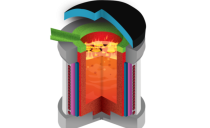

HeatKing™ product portfolio consists of selected refractory products that were developed for an optimized performance in each zone of the coreless induction furnace (coil coat, working lining, spout and top cap mix). An improved lifetime, homogeneous wear pattern and safe operations have been reported by our customers.

Advantages

Performances

Customers using HeatKing™ solutions in their coreless induction furnaces can benefit from the following --

- Improvement in melt shop and maintenance interval planning

- Working lining exhibiting low reaction with the metal or slag

- Higher metal purity thanks to higher chemical resistance and less inclusions in finished metal

- Compatible with metallurgical treatment of the metal in the coreless induction furnace, e.g. dephosphorization process

- Higher productivity and lower downtime of melting operations

- Reduced CO2 emission levels

- Optimized lining thickness allowing maximum and quick induction heating

- Overall benefit on melting operations costs

- High alloy recovery

For more information, please visit our HeatKing™ monolithic lining solutions website or contact us.

Related Content

HeatKing Monolithic Lining

HeatKing™ range of high performance refractory products are designed for use in extreme operating conditions, delivering enhanced performance.

Coreless Induction Furnace

Saint-Gobain Performance Ceramics & Refractories’ extensive portfolio of solutions for coreless induction furnaces supports customers to enhance safety and...

Foundry

Saint-Gobain Performance Ceramics & Refractories leverages its extensive expertise to provide innovative, reliable refractory solutions for all ferrous and...