Waste to Energy

Reliable Refractory Materials for High-Performance Energy Recovery

Waste-to-energy systems operate under constant thermal, chemical, and mechanical stress, requiring materials that can endure extreme conditions. To meet these challenges, we develop silicon carbide (SiC) solutions tailored for high-performance in demanding environments. Our portfolio of bricks, tiles, refractory blocks, and tube wall protection systems delivers a balance of thermal conductivity and structural strength to support combustion stability, improve energy recovery, and safeguard critical infrastructure.

Each solution is precisely designed to fit both new installations and retrofit projects. Supported by expert technical guidance, our SiC technologies help reduce maintenance needs, extend service life, and maintain high performance even in the most demanding operating environments.

Waste to Energy Technologies

Click on the button to find more:

- Back Cast SiC Tube Wall Tile Systems

- Mortar SiC Tube Wall Systems

- Custom Designed SiC Tube Wall: Tile or Brick

- Air Tiles

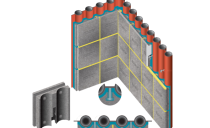

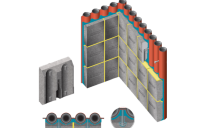

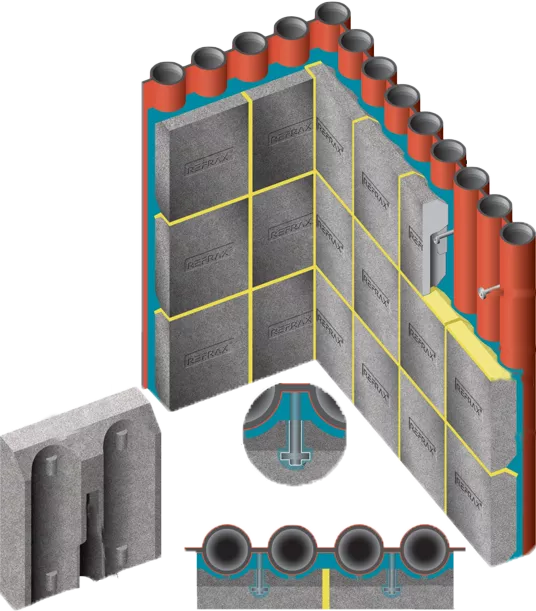

Back Cast SiC Tube Wall Tile Systems

The T-Clip® PRO System is ideal for vertical boiler tube walls and slanted walls on ceilings and roof sections. Advanced design coupled with self-leveling backfill materials such as Refrax® Plusflow ensure optimal protection alongside rapid and efficient lining installation.

The T-Clip® PRO System offers a number of benefits including:

- High thermal conductivity and increased thermal recovery

- Lower mean temperature

- Superior oxidation resistance

- High mechanical load capability

- Quick, precisely defined and flexible installation

- Compatibility with a wide range of tube diameters and spacings

- Adjustable anchor allowing for some compensation of distorted walls

- Easy maintenance of expansion around tiles due to straight sides

| Equipment | Product | Characteristics | Application | Benefits |

| Tile System | T-Clip® PROform | Profiled tile High Efficiency Lower mean temperature |

All tubewall applications incl. roof sections | Reduced oxidation due to lower tile mean temperature |

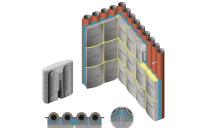

| T-Clip® PRO | Straight sides Single fixing |

All tubewall applications incl. roof sections | Fast installation, long lasting, high flexibility at temperature. Easy maintenance of expansion around tiles due to straight sides. |

|

| T-Clip® | Tile with overlap sides | All tubewall applications incl. roof sections | Joint area protected by overlap |

I can confirm once again the Saint-Gobain T-Clip® PRO tile system is extremely effective in our Boiler. With three years of service since the original installation, we have no issues and as we observed its still in perfect condition. Using the T-Clip® PRO tile system has proven very effective for us protecting the tube wall & eliminating the issues we had previously. It is highly recommended and we are pleased to have had this system introduced to us.

Actually, we are now at the stage where all sections requiring reline are complete, so will only need very limited spares in the future, but following the positive experience working with you & Saint-Gobain, we will look for other areas where we can collaborate and solve any problems we have.

Thanks for your help and making maintaining our facility moving forward much easier.

Dalkia Waste to Energy Plant Manager

FAQ

Is the T-Clip® PRO system suitable for all areas of the combustion chamber?

Yes. Several material grades can be used with the T-Clip® PRO system, and it is possible to provide a custom design solution for any tube wall area.

Is this design available for a tube pitch of 100 mm?

Yes. 100 mm pitch is available alongside many other sizes. Saint-Gobain Performance Ceramics & Refractories’ team of experts is on hand to discuss any particular sizing requirements.

Where is this system manufactured?

Saint-Gobain Performance Ceramics & Refractories is a global company with several manufacturing facilities around the world. As such, supply can be tailored to meet customer requirements.