Direct Reduced Iron Technology

As Direct Reduced Iron (DRI) technology increasingly replaces traditional blast furnaces, the ironmaking industry is shifting towards more sustainable and cost-effective solutions. Unlike blast furnace processes, DRI uses reducing agents such as hydrogen (H₂), carbon monoxide (CO), methane (CH₄), and coal, significantly lowering CO₂ emissions. This gas–solid reduction process involves complex thermal and chemical interactions, requiring refractories that can withstand unique gas-solid phase flows and interfacial reactions. At Saint-Gobain Performance Ceramics & Refractories, we are at the forefront of developing advanced refractory solutions tailored for DRI shaft furnaces supporting the industry's transition to carbon neutrality by 2050 through innovative materials engineered for performance, durability, and environmental impact reduction.

Solution By Application

Click on your application to find more:

- Direct Reduced Iron

Introducing CORSHIELD™

Innovative refractories for DRI applications

Direct Reduced Iron (DRI) is transforming iron production by providing a more environment friendly alternative to the traditional blast furnace route.

As the industry advances towards low CO emission iron and steel making, the demand for cutting-edge refractory solutions that can withstand the unique challenges of DRI shaft furnaces, especially with elevated hydrogen (H2) levels, is growing.

Our refractory bricks are engineered to meet these demands, offering sustainability combined with durability towards abrasion and complex gas corrosion. Rely on our innovative materials to boost the effciency and longevity of your DRI processes.

IMPROVED LIFETIME

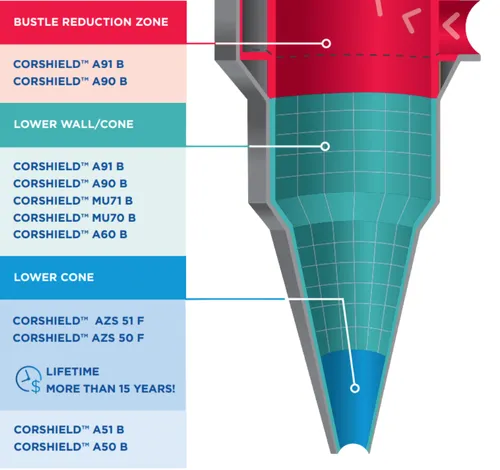

More than 15 years durability reported for the lower cone area.

GAS CORROSION RESISTANCE

Highly effective in contact with reducing gases, from reformed natural gas inlets to hydrogen boosting.

ABRASION RESISTANT

Engineered to withstand the harsh conditions relative to the continuous flow of solid pellets.

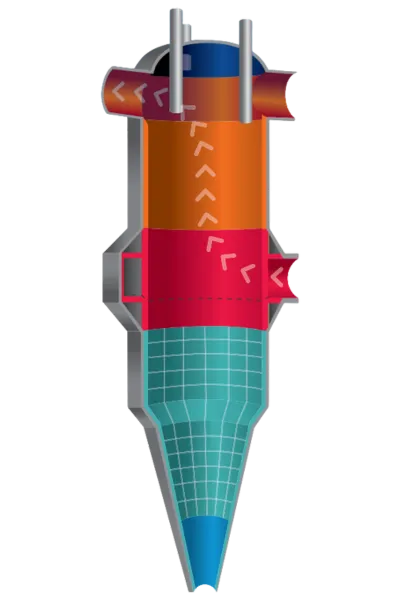

Enhance your DRI shaft furnace with CORSHIELD™

Saint-Gobain Performance Ceramics & Refractories specializes in high-quality refractory bricks for critical areas in direct contact with iron ore pellets and corrosive atmospheres. Our range includes High Alumina, Mullite, and Fused Cast AZS refractories, ensuring topnotch quality and reliability.

CORSHIELD™ refractory solutions are designed to support the transition towards Low-CO_ iron and steelmaking, ensuring long service life and optimal performance in DRI applications.

We cover the entire furnace, from the upper shaft to the lower cone, with tailored solutions for each zone. Our primary focus is on the hot face, guaranteeing optimal performance and durability in the harshest conditions.

Documents

Want to know more?

Connect with our experts today to discover the development opportunities that await you. Click the button below to complete the form, and we would be thrilled to support you on your journey.

FAQ

How does CORSHIELD™ meet the technical demands of modern DRI furnaces?

Key areas of the DRI furnace, such as the lower cone, bustle, and transition zones, are exposed to extreme thermal, chemical, and mechanical conditions. Our Corshield™ solutions are specifically engineered to increase the lifespan of these critical zones by countering abrasion and complex gas corrosion. By enhancing durability and reducing wear, they help minimize unplanned maintenance and extend furnace availability, contributing to more stable and cost-effective operations.

How is CORSHIELD™ sustainable?

CORSHIELD™ is manufactured in Ecovadis-certified facilities as:

- Silver in Halol, India;

- Gold in Palakkad, India.

Additionally, using 100 % green energy in our Italian Ecovadis-certified facility:

- Platinum in Mezzocorona, Italy.

What is the lifespan of CORSHIELD products?

As an example for the lower cone, DRI furnace operators have reported performance exceeding 15 years, significantly reducing maintenance and replacement needs.