- Enhanced erosion performance over market available Reaction Bonded Silicon Carbide.

- Large shape capability.

- Complex shape capability.

Upgrade to HAMMERfrax® tooling free, if you currently have parts being made out of our Norfrax (RBSiC) or Cryston® (NBSiC)

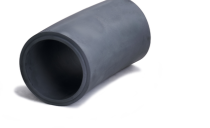

Typical shapes from ¼” (6.3 mm) up to 2” (50.8 mm) wall thickness in cylinders, discs, elbows, tees, Wye’s, cones, bricks, blocks.

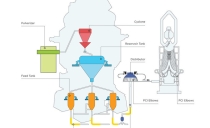

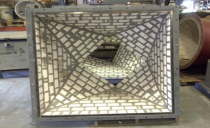

Ceramic Cyclone Linings

Discover Saint-Gobain Performance Ceramics & Refractories’ extensive range of ceramic cyclone linings.

Elbows, Pipes and Fittings Linings

Discover Saint-Gobain Performance Ceramics & Refractories’ extensive range of cost-effective wear resistance solutions – able to extend the service life of...

Ceramic Ductwork Linings

Discover Saint-Gobain Performance Ceramics & Refractories’ extensive range of ceramic ductwork linings.

Wear Resistant Technologies

Saint-Gobain Performance Ceramics and Refractories have developed a range of wear resistant technologies using alumina oxides (Al2O3 and ZTA) as well as...

Crushing, Pulverizing, and Grinding Components

Discover Saint-Gobain Performance Ceramics & Refractories’ extensive range of cost-effective wear resistance solutions for crushing, pulverizing and...

Separation and Screening Components

Discover Saint-Gobain Performance Ceramics & Refractories’ extensive range of cost-effective wear resistance solutions for separation and screening...

Belt Conveyor Components

Discover Saint-Gobain Performance Ceramics & Refractories’ extensive range of cost-effective wear resistance solutions for belt conveyor components.