Ceramic Solutions for Wire Galvanising Processes

Wire galvanising plays a crucial role in enhancing the corrosion resistance of steel wires by coating them with zinc. In these processes, specialised ceramic components are vital for ensuring efficiency and durability. This blog post aims to explore the importance of ceramic solutions, their unique properties, and applications in wire galvanising plants.

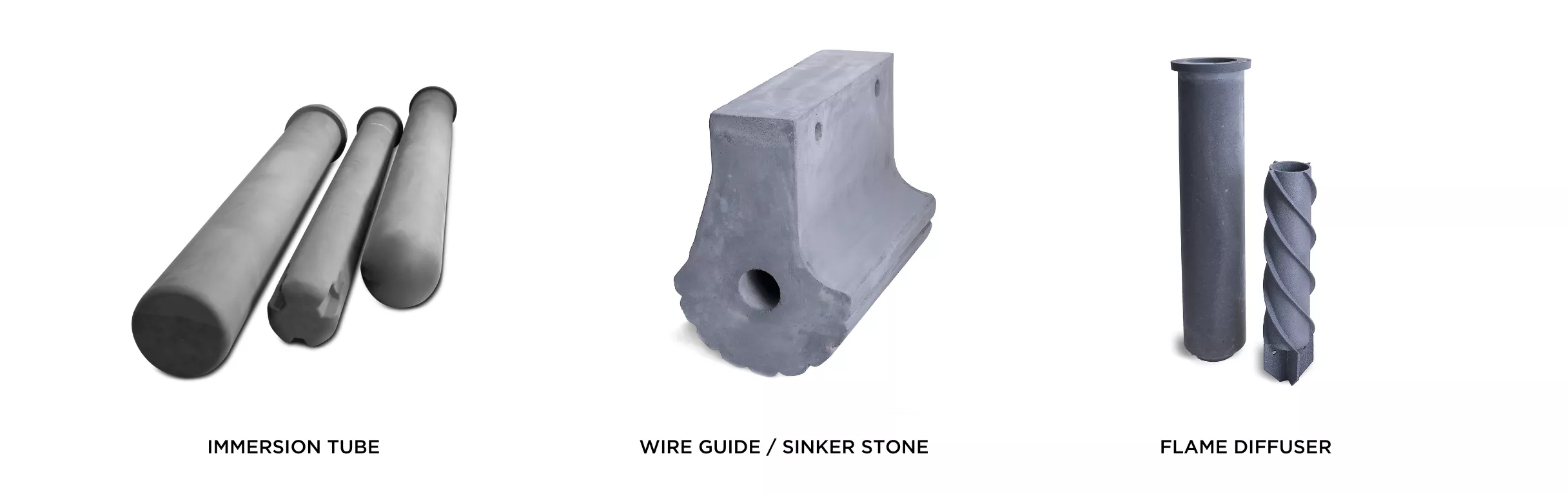

Ceramic Components in Wire Galvanising

Ceramic solutions in wire galvanising primarily include high-performance immersion tubes and other specialised components. Unlike traditional refractories used in zinc kettle linings, these ceramic components are designed for specific functions within the galvanising process. For example, Cryston® Max immersion tubes, made from advanced ceramic materials, offer exceptional performance under the challenging conditions of wire galvanising.

Advantages of Ceramic Solutions

Using these ceramic components in wire galvanising brings several benefits:

- Enhanced Thermal Stability: Ceramics provide superior thermal resistance, crucial for maintaining consistent temperatures during the galvanising process.

- Durability: These components exhibit remarkable longevity, reducing the need for frequent replacements and minimizing downtime.

- Cost-Effectiveness: The extended service life and reduced maintenance needs of ceramic components translate into significant cost savings over time.

Applications in Wire Galvanising

In wire galvanising plants, ceramic components find their application in several critical areas:

- Immersion Tubes: Are used to keep zinc alloys molten and temperature-controlled during the zinc galvanising process.

- Sinker Stones and Sliders: Ceramic sinker stones and sliders are employed for their wear resistance and longevity.

- Guides and Beams: These components are crucial for maintaining the structural integrity and efficiency of the galvanising line.

Ceramic Solutions from Saint-Gobain

Saint-Gobain Performance Ceramics & Refractories specializes in providing ceramic solutions tailored for wire galvanising plants. Leveraging advanced materials and engineering expertise, Saint-Gobain ensures that its ceramic components meet the highest performance and durability standards, driving advancements in wire galvanising technology.

Ceramic solutions are integral to the modern wire galvanising industry, offering enhanced performance, durability, and cost-effectiveness. As the industry evolves, the role of these components becomes increasingly vital. For more information on how our ceramic solutions can enhance your wire galvanising processes, contact Saint-Gobain Performance Ceramics & Refractories today.

Further Reading: Ceramics For Wire Galvanizing Cryston® Max Immersion Tubes

Cryston® Max Immersion Heater Tubes & Flame Diffuzer

Saint-Gobain Performance Ceramics & Refractories’ immersion heating tubes offer superior performance and reliability.

SpyroCor and NOxBuster Radiant Tube Insert

Discover Saint-Gobain Performance Ceramics & Refractories’ range of radiant tube inserts – ideal for improving efficiency in the furnace chamber.

Cast Refrax

Cast Refrax silicon nitride bonded silicon carbide refractory,is chemically inert to most materials.