Wear Resistant Technologies

Saint-Gobain Performance Ceramics & Refractories’ innovative Wear Resistance Technologies business unit, can manufacture a wide range of different high grade ceramic materials.

Wear Resistance Technologies can customize products and soliutions according to customers’ abrasion, erosion and corrosion needs. Our core objective is to ensure the optimum performance, efficiency and service life of customers’ equipment and systems; while aligning our values on sustaibability and carbon free goals

.

Solution By Equipment

Click on your equipment to find more:

- Blast Furnace Charging Systems

- Crushing, Pulverizing, and Grinding Components

- Separation and Screening Components

- Piping Components

- Belt Conveyor Components

- Sinter Plant

Crushing, Pulverizing, and Grinding Components

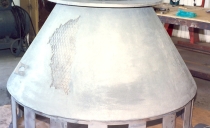

Grinding machines are subject to severe wearing forces every operational run. Crushing and pulverizing components designed to reduce the particle size of hard materials will gradually succumb to wear, requiring regular maintenance to ensure optimal performance. Yet most grinding, crushing, and pulverizing components will need replacing due to irreversible wear. The latest wear-resistant technology can significantly reduce repair and maintenance costs providing long-lasting solutions at a cost-effective upfront investment.

Saint-Gobain Performance Refractories & Ceramics offers a suite of wear-resistant solutions for grinding, crushing, and pulverizing applications. Our solutions offer the highest wear resistance on the market, increasing system uptime by extending the maintenance-free service lives of critical components. This helps create more sustainable grinding processes in industrial applications.

Our products, available in high-performance refractories materials from a variety of silicon carbides (SiC), include:

- Micronizers

- Jet mills

- Vertical shaft impactors

- Bead mills

- Attritors

- Ball mills

- Roller mills

Explore our various ceramic solutions and key products below.

Ceramic Solution

| Alpha Al2O3 | Zirconia Toughned Alumina | |

| Durafrax® | Durastrike® ZTA | |

| Sliding Abrasion | +++ | ++++ |

| Erosion | +++ | ++++ |

| Impact | + | +++ |

| Corrosion Resistance | ++ | ++ |

| Thermal Shock | + | ++ |

| Thermal Insulation | + | + |

| Electrical Insulation | ++++ | +++ |

| Nitride Bonded SiC | Reaction Bonded SiC | Sintered Alpha SiC | ||||||||

| Cryston® | Cryston® TW | Cast Refrax® 20 | Refrax® 20 | Norfrax® RB | Silit® SKD | HAMMERfrax® | Hexoloy® | |||

| Sliding Abrasion | + | ++ | + | + | +++ | +++ | ++++ | ++++ | ||

| Erosion | + | + | + | + | ++ | ++ | +++ | ++++ | ||

| Impact | ++ | + | + | + | + | + | ++ | + | ||

| Corrosion Resistance | ++ | ++ | ++ | ++ | +++ | +++ | ++ | ++++ | ||

| Thermal Shock | + | ++ | ++ | ++ | ++ | ++ | ++ | ++ | ||

| Thermal Insulation | ++ | ++ | ++ | +++ | + | + | + | + | ||

| Electrical Insulation | NA | NA | NA | NA | NA | NA | NA | NA | ||

| Fused Cast AZS | Zirconia Toughned Alumina | |

| ZAC - Corguard® | Durastrike® ZTA | |

| Sliding Abrasion | ++ | ++++ |

| Erosion | ++ | ++++ |

| Impact | +++ | +++ |

| Corrosion Resistance | ++ | ++ |

| Thermal Shock | ++ | ++ |

| Thermal Insulation | ++ | + |

| Electrical Insulation | ++ | +++ |

| Silicon Carbide | Aluminium Oxide | |

| Wearfrax® RS58 | Wearfrax® RA57 | |

| Sliding Abrasion | + | + |

| Erosion | + | + |

| Impact | + | + |

| Corrosion Resistance | + | + |

| Thermal Shock | ++ | + |

| Thermal Insulation | ++ | + |

| Electrical Insulation | NA | NA |

Documents

FAQ

Does Saint-Gobain Performance Ceramics & Refractories work with customers with no prior history of using ceramics?

Saint-Gobain Performance Ceramics & Refractories frequently works with customers who have not used ceramics previously.

The company’s teams of experienced engineers will conduct a comprehensive review of all aspects of a system application, asking questions and performing a thorough evaluation to ascertain if a customer could utilize ceramics or a related material (even if Saint-Gobain Performance Ceramics & Refractories does not currently manufacture this).

A reliable, cost-effective, and robust solution is likely possible in every scenario.

How well do ceramics perform in impact zones?

Impact is a very general term. More specifically, ceramics have very limited flexibility, with tension causing cracks or breakages.

Saint-Gobain Performance Ceramics & Refractories specifically designs ceramic materials to eliminate or reduce these characteristics, ensuring excellent performance.

What does a wear audit typically entail?

A typical wear audit will either target part of the system or the entire system. Data collected includes process/operations information, wear history for each component, and wear life. A mutual NDA can be signed if required.

Review drawings and a written summary of each component evaluated are provided to the customer, along with a series of recommendations for improvement.