Wear Resistant Technologies

Saint-Gobain Performance Ceramics & Refractories’ innovative Wear Resistance Technologies business unit, can manufacture a wide range of different high grade ceramic materials.

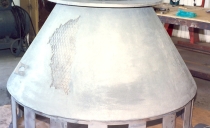

Wear Resistance Technologies can customize products and soliutions according to customers’ abrasion, erosion and corrosion needs. Our core objective is to ensure the optimum performance, efficiency and service life of customers’ equipment and systems; while aligning our values on sustaibability and carbon free goals.

Solution By Equipment

Click on your equipment to find more:

Piping Components

Saint-Gobain Performance Ceramics & Refractories’ ceramic lining solutions can significantly reduce the need for maintenance, hole or leak repairs on piping systems; whether these are hydraulic, pneumatic, vacuum or gravity based.

Lining systems are available to address wear and corrosion issues affecting plant reliability and safety in a range of systems, including:

- Complex elbow

- Lateral

- Carbon steel tee or reducer

- Hardened pipe

- Weld-overlay

- Nickel alloys

- HDPE

- Rubber

Materials such as Cryston®, Durafrax®, Norfrax®and Hexoloy® are ideal for use in demanding piping applications, particularly those requiring constant patching of elbows and leaks, which can lead to safety concerns, downtime and cost implications.

Ceramic Solutions

| Alpha Al2O3 | Zirconia Toughned Alumina | |

| Durafrax® | Durastrike® ZTA | |

| Sliding Abrasion | +++ | ++++ |

| Erosion | +++ | ++++ |

| Impact | + | +++ |

| Corrosion Resistance | ++ | ++ |

| Thermal Shock | + | ++ |

| Thermal Insulation | + | + |

| Electrical Insulation | ++++ | +++ |

| Nitride Bonded SiC | Reaction Bonded SiC | Sintered Alpha SiC | ||||||||

| Cryston® | Cryston® TW | Cast Refrax® 20 | Refrax® 20 | Norfrax® RB | Silit® SKD | HAMMERfrax® | Hexoloy® | |||

| Sliding Abrasion | + | ++ | + | + | +++ | +++ | ++++ | ++++ | ||

| Erosion | + | + | + | + | ++ | ++ | +++ | ++++ | ||

| Impact | ++ | + | + | + | + | + | ++ | + | ||

| Corrosion Resistance | ++ | ++ | ++ | ++ | +++ | +++ | ++ | ++++ | ||

| Thermal Shock | + | ++ | ++ | ++ | ++ | ++ | ++ | ++ | ||

| Thermal Insulation | ++ | ++ | ++ | +++ | + | + | + | + | ||

| Electrical Insulation | NA | NA | NA | NA | NA | NA | NA | NA | ||

| Fused Cast AZS | Zirconia Toughned Alumina | |

| ZAC - Corguard® | Durastrike® ZTA | |

| Sliding Abrasion | ++ | ++++ |

| Erosion | ++ | ++++ |

| Impact | +++ | +++ |

| Corrosion Resistance | ++ | ++ |

| Thermal Shock | ++ | ++ |

| Thermal Insulation | ++ | + |

| Electrical Insulation | ++ | +++ |

| Silicon Carbide | Aluminium Oxide | |

| Wearfrax® RS58 | Wearfrax® RA57 | |

| Sliding Abrasion | + | + |

| Erosion | + | + |

| Impact | + | + |

| Corrosion Resistance | + | + |

| Thermal Shock | ++ | + |

| Thermal Insulation | ++ | + |

| Electrical Insulation | NA | NA |

Documents

FAQ

How difficult is it to adapt a ceramic lining to a particular system?

Ceramics can be easily adapted to work with almost all pipes and fittings while meeting any required pipe standards.

Is there a risk of incompatible lining thickness and mismatched inner diameters?

This is a common issue but not a cause for concern. Saint-Gobain Performance Ceramics & Refractories’ team of experienced engineers will carefully match the inner diameter of the system or unlined components being connected or designing for, adapting these to accommodate any pipe connections currently in use.