Why Choose Silicon Carbide for Kiln Furniture Components?

Silicon carbide is perfect for creating kiln furniture because of its hardness and chemical and thermal shock resistance.

In the realm of high-temperature applications, particularly in kilns, selecting suitable materials for kiln furniture is paramount. Silicon carbide (SiC) emerges as a superior choice, offering a blend of exceptional properties that meet the demanding requirements of kiln environments. This article delves into the benefits of using SiC, specifically in the context of kiln furniture components.

The Basics of SiC

SiC is industrially produced through the Acheson process, as it is not naturally occurring in sufficient quantities (moissanite). Its mechanical properties make it ideal for:

• Cutting tools

• Grinding wheels

• High-temperature resistant structures

Exceptional Hardness and Mechanical Strength

SiC's extraordinary hardness is crucial in environments where physical abrasion and wear are constant concerns. It maintains structural integrity and surface smoothness over extended periods, even under abrasive conditions.

Additionally, SiC exhibits outstanding mechanical strength at elevated temperatures. This is crucial as kiln furniture must maintain shape and strength at high temperatures, often reaching up to 1600°C. SiC's ability to withstand extreme conditions without deformation ensures consistent kiln performance and product quality.

Thermal Shock Resistance and Conductivity

SiC excels in thermal shock resistance due to its low thermal expansion, tolerating rapid temperature changes without cracking or deteriorating. This property is valuable in kilns where temperatures fluctuate frequently, ensuring the longevity and reliability of kiln furniture.

Moreover, SiC's high thermal conductivity facilitates efficient heat distribution within the kiln, essential for achieving consistent firing results and maintaining energy efficiency, thus reducing operational costs.

Oxidation and Chemical Resistance

SiC's inherent chemical inertness makes it resistant to oxidation and corrosion, even in chemically aggressive kiln environments. This resistance prolongs the life of kiln furniture, ensuring performance over time and preventing chemical interactions from compromising the quality of fired products.

Additional Benefits: Electric Conductivity

As a semiconductor, SiC provides impressive electric resistance against high levels of voltage. It can offer this because of its:

These characteristics make it ideal for use in electric furnaces, chargers for batteries, and control systems.

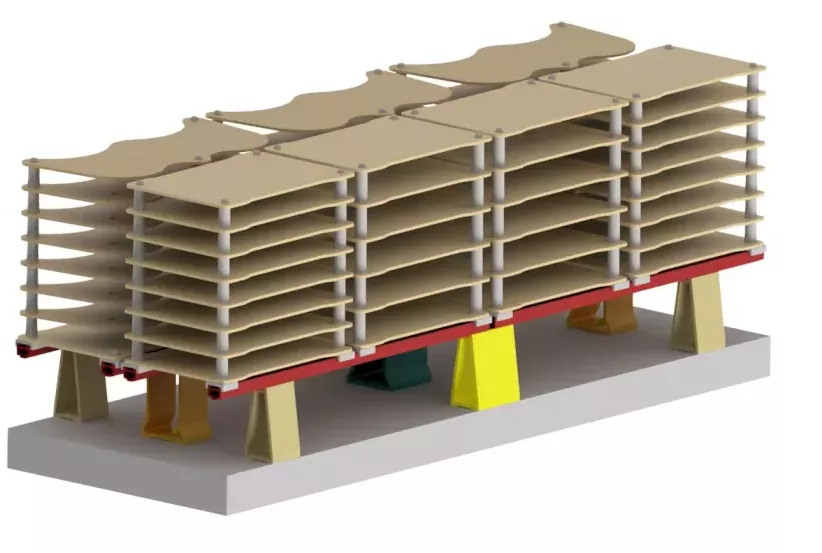

Application in LO-MASS® Kiln Furniture and Recrystallized Components

The application of SiC in LO-MASS® kiln furniture exemplifies its suitability for high-performance kiln environments. These components, developed by Saint-Gobain, leverage SiC's unique properties to produce lightweight yet robust solutions for kiln furniture. The reduced mass of LO-MASS® components enabled by SiC's properties and Saint-Gobain's production methods translates to lower energy consumption and faster heat-up and cool-down cycles, enhancing overall kiln efficiency.

Furthermore, recrystallized SiC lug posts and tubes demonstrate SiC's adaptability in various kiln applications, including refractory linings. These components offer enhanced strength and longevity, ideal for continuous and demanding kiln operations.

Environmental Considerations

In an era where environmental impact is a growing concern, the choice of materials for kiln furniture needs to consider sustainability. SiC's durability and efficiency contribute to reduced energy consumption and lower emissions in kiln operations. Additionally, the extended lifespan of SiC components means fewer replacements and less waste, aligning with sustainable manufacturing practices.

Utilizing SiC As Your Kiln Material Of Choice

SiC is an exemplary material for kiln furniture due to its exceptional hardness, mechanical strength at high temperatures, thermal shock resistance, thermal conductivity, and chemical inertness. The implementation of SiC in products like LO-MASS® kiln furniture and recrystallized components further underscores its suitability for demanding kiln applications. With benefits in energy efficiency and environmental sustainability, SiC presents itself as the clear choice for modern kiln furniture needs.

Elevate Your Kiln Performance with Sustainable Innovation

At Saint-Gobain Performance Ceramics & Refractories, we understand the pivotal role of kiln furniture in your operations. That's why we're committed to offering you the most advanced solutions in the industry. Our Silicon Carbide-based LO-MASS® kiln furniture isn't just a testament to superior performance and durability; it's a step towards a more sustainable future.

By choosing our SiC kiln furniture, you're not only ensuring exceptional quality and efficiency in your kiln operations but also contributing to a greener manufacturing process. Our products are designed to reduce energy consumption and lower emissions, aligning with your sustainability goals.

Take a step towards enhanced performance and environmental responsibility. Explore our range of silicon carbide kiln furniture today and join us in shaping a sustainable future.

Related Content

LO-MASS® Kiln Furniture

Discover Saint-Gobain Performance Ceramics & Refractories’ comprehensive range of solutions and materials for kilns and furnaces, including kiln furniture...

Silicon Carbide (SiC)

Silicon carbide ceramics for a range of industries, including electronics.

Systems for Kilns & Furnaces

Discover Saint-Gobain Performance Ceramics & Refractories’ comprehensive range of ceramic products and solutions - designed, developed, and manufactured...

Want to know more?

Contact our experts now to explore the development opportunities that await you. Click the button below to fill out the form, and we will be delighted to accompany you on your journey.