Next Generation Refractory Solutions for Steelmaking through Coreless Induction Furnace

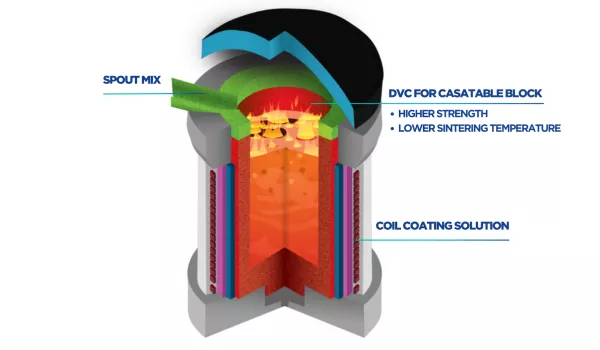

HeatKing™ introduces an advanced monolithic lining solution designed to optimize steel melting processes in coreless induction furnaces. Its unique structure guarantees superior steel quality, reduced cost per unit, improved productivity, enhanced safety, energy efficiency, and sustainability.

Our HeatKing™ range includes solutions for working linings, furnace tops, spouts, and coil coatings, enabling customers to operate with maximum efficiency and reliability.

Interested in our Products, application engineering or lining services? Click here to connect!

Solution By Application

Click on your application to find more:

Lining Application Service for Coreless Induction Furnaces

Saint-Gobain Performance Ceramics and Refractories offers an exclusive Refractory Lining Application Service tailored for Coreless Induction Furnaces. Our dedicated team of expert application engineers is available on-site to ensure the refractory linings are applied with precision, resulting in optimal performance for your steel melting operations. By partnering with us, you gain access to unparalleled expertise and the superior performance of our HeatKing™ Neutral Ramming Mass, an unmatched value proposition in the induction furnace industry.

by unmatched application technique

by highly skilled application team

of process, safety and equipment

on-site or virtual

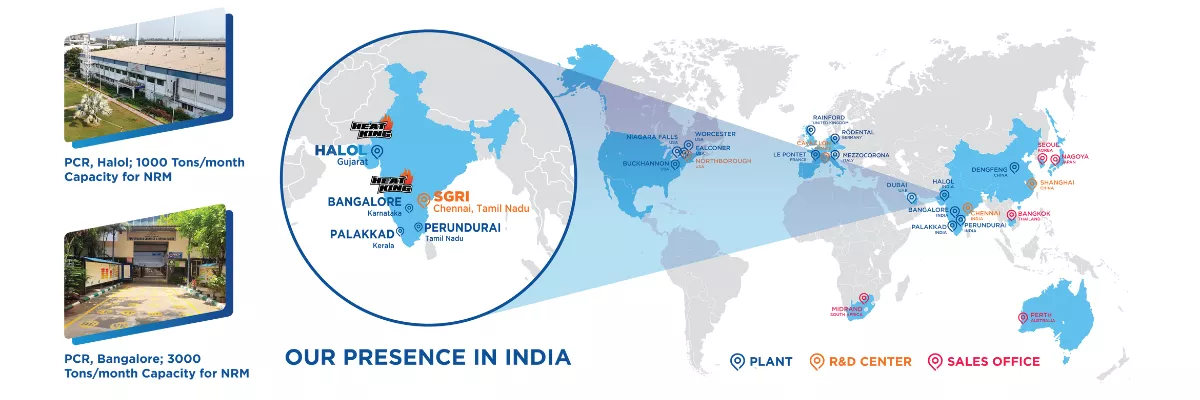

Manufacturing and Supply locations in India

The Heatking range of induction furnace lining solutions serves customers across India, Bangladesh, Nepal & Bhutan.