Using Silicon Carbide in Industrial Metrology

Mankind’s industrial endeavors have advanced in waves associated with distinct revolutionary eras. When engineers and historians study the steady advance towards modernization, the academic and social changes of the time are often overlooked. We focus on the technical innovations that promoted automation – a habit perpetuated today with the onset of Industry 4.0.

However, foundational cultural changes in the way manufacturing is carried out have proven just as fundamental to our success as an industrial species. Metrology, for instance.

What is Metrology?

Industrial metrology, also known as applied or technical metrology, refers most commonly to quality assurance (QA). It covers the many interlinked tasks involved in process control including testing to ensure the suitability and calibration of semi-finished and finished goods via robust testing and measurement. Each part in a complex mechanical system, for instance, must be made to exacting tolerances to ensure pain-free assembly and end-product functionality.

What is a CMM?

A CMM is a bridge-style measuring system that probes the geometry of objects along X, Y, and Z axes using an optical system or touch-trigger. The materials used in CMM construction typically require high specific stiffness and good thermal properties to enable thermally dynamic testing and measurement. Historically, the best materials have been a combination of aluminum, granite, and steel. However, when sub-micron accuracy is required, these traditional materials are not adequate.

At Saint-Gobain Performance Ceramics & Refractories, we deliver MM solutions based on precision silicon carbide (SiC). With a specific stiffness of 86 – 132, our silicon carbide products far exceed the performance of conventional industrial metrology materials by a minimum factor of 25%. This comes courtesy of significant weight savings too.

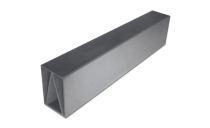

We engineer silicon carbide beams, bridges, guide rails, and more for CMM assemblies. With low thermal expansion of less than 50% that of aluminum, and exceptionally high thermal stability, silicon carbide represents an enormous step-up in terms of metrological performance.

If you would like to discuss our silicon carbide brands for industrial metrology applications, simply contact a member of the Saint-Gobain team.

Related Content

Specialty Ceramics

Saint-Gobain Performance Ceramics & Refractories’ extensive range of specialty ceramic products – ideal for use in the harsh environments typical in broad...

Metrology Ceramics for CMM & Motion Control Equipment

Advancer® NSiC and Silit® SKD SiSiC products -- ceramic solutions for high accuracy CMM and Motion Control equipment.

Silicon Carbide (SiC)

Silicon carbide ceramics for a range of industries, including electronics.