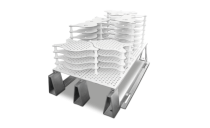

Kiln & Furnace Systems Solutions

Saint-Gobain Performance Ceramics & Refractories’ products and solutions for kilns and furnaces are specifically designed and developed to facilitate consistent and long-term performance at high temperatures (up to 1,800°C) and under severe operating conditions.

Solutions are available for all common types of kilns and furnaces across a wide range of industries.

Ceramic Solution By Application

Click on your application to find more: