Total Burner Solutions with Carbon Reduction Technologies

Industrial burner solutions are in the firing line when it comes to sustainability. Thermal processes are a significant source of energy consumption and emissions generation, making them a critical target for innovation under green initiatives. Process managers are now responsible for not only driving productivity and maintaining equipment over as many duty cycles as possible, but also for reducing overall energy usage and finding solutions for carbon dioxide reduction.

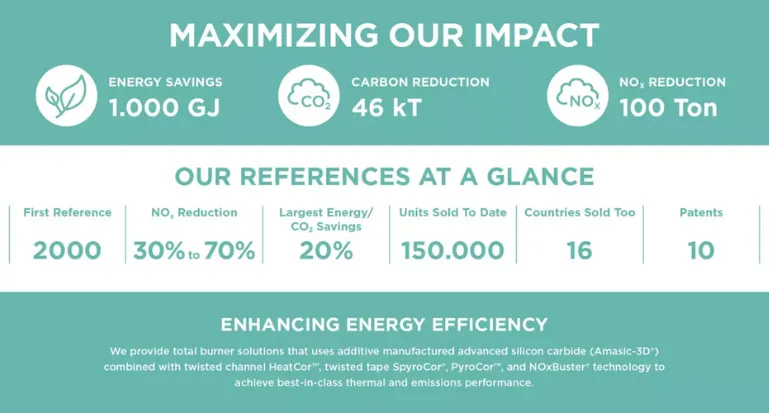

At Saint-Gobain Performance Ceramics & Refractories, we collaborate with valued partners to continually innovate and engineer products that meet ever-changing customer needs. Our total burner solutions are the culmination of significant research and development (R&D) into ultra-high-performance heaters for critical use cases, from aluminium and foundry applications to chemical processing industries (CPI). Our mission is to deliver efficient burner solutions that help you meet your energy efficiency, productivity, and sustainability goals.

Enhancing Energy Efficiency

Carbon Dioxide Reduction

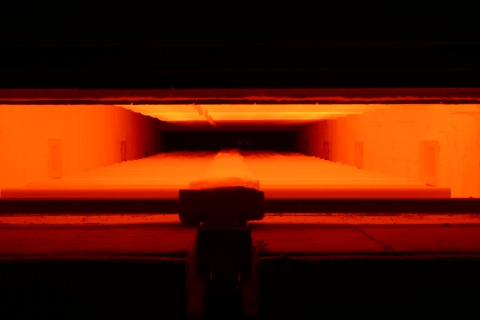

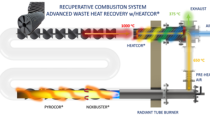

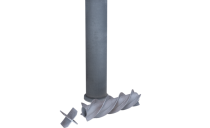

Energy savings naturally translate to direct carbon dioxide reduction. Our products include single-ended radiant tubes, U-tubes and W-tubes, each boasting enhanced design solutions and carefully selected materials to ensure optimal performance and efficiency. Silit® ceramic radiant tubes, recuperators, flame tubes, and combustors are all established, proven and time-tested designs. Not only do these systems assist in saving energy, but they also support carbon dioxide reduction and reduce the need for maintenance. For example, our radiant, u and w-tubes are all fitted with recuperators. Recuperators play a big role in energy efficiency because they help to recover waste heat energy and repurpose it.

Carbon dioxide reductions are on par with energy savings, and with retrofit capabilities and significant ease-of-installation, users can realise as between 5 - 20 % emissions reductions with 24 months of installation.

Whether you are using single-ended radiant tubes, u-tubes or w-tubes, you can find out more about what we offer for each one by clicking on one of the buttons below.

For more information on total burner solutions for high-temperature applications, why not watch our video below. We explain how we develop solutions for your toughest challenges, enabling you to streamline processes and improve efficiency.