Systems for Kilns and Furnaces

Saint-Gobain Performance Ceramics & Refractories’ products and solutions for kilns and furnaces are specifically designed and developed to facilitate consistent and long-term performance at high temperatures (up to 1,800°C) and under severe operating conditions.

Solutions are available for all common types of kilns and furnaces across a wide range of industries.

Ceramic Solution By Application

Click on your application to find more:

Improving Performance at Cathode Active Material (CAM) Producers

When it comes to optimizing the cost and performance of lithium-ion batteries, few pathways are more impactful than enhancing cathode active material (CAM) production. The cathode accounts for nearly 40% of the overall cost of a cell. By leveraging Saint-Gobain’s comprehensive portfolio of ceramic solutions, CAM producers can significantly boost their production capacity and profitability while minimizing operating costs and maintenance downtime associated with roller hearth kiln (RHK) operations.

Saint-Gobain’s recycling solutions for end-of-life ceramics offer producers alternative streams for their ceramic waste. This approach reduces dependence on raw materials and lowers the supply chain’s environmental footprint, aligning with Saint-Gobain’s mission of “Making the World a Better Home.”

Our robust PowerCeram™ saggers, along with Silit® SK and Hexoloy® SE rollers, set the industry standard for high-performing, reliable solutions that optimize RHK operations. These innovations enable higher profitability and reduced costs for CAM producers.

Key Benefits of Our Saggers and Rollers

- Extended Service Life

- Increased CAM Capacity

- Reduced Ceramic Waste

- Increased Energy Efficiency

- High wear, corrosion, and chemical resistance

- Robust mechanical strength

- High product quality and reliability

- Increased service temperatures that reach 1,380°C

- Improved corrosion, chemical, and oxidation resistance

- Maximized mechanical strength

- Long service life

- Increased service temperatures that approach 1,750°C

Material Description and Applications

Versatile Use in RHKs: Hexoloy® and Silit® rollers, along with our saggers, are integral to the operation of roller hearth kilns. These kilns produce a wide range of products, including electronic components and lithium-ion battery materials like cathode active material (CAM). Rollers transport saggers through different kiln zones, ensuring consistent heating and efficient material processing.

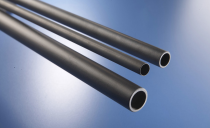

Silicon Carbide Rollers: Our rollers, made from high-quality silicon carbide (SiC), are engineered to endure the cyclical loading of saggers at elevated temperatures in corrosive environments. These rollers are designed to meet the stringent demands of roller hearth kiln (RHK) operators, ensuring maximum roller lifespan and minimal deflection. Improper material selection or construction can lead to roller failure and sagger misalignment, causing damage and increased kiln downtime.

Preferred Roller Materials: Silit® SK and Hexoloy® SE rollers from Saint-Gobain Performance Ceramics & Refractories are the top choices for RHKs due to their superior performance and reliability. These rollers can be specified for new kilns, or our engineering team can assist in selecting and supplying replacement rollers for existing kilns.

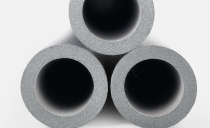

High-Performance Saggers: Saggers are essential for containing and conveying products through the rapid heating, high-temperature, and corrosive zones of RHKs. Properly designed saggers maintain structural integrity, resist chemical corrosion from lithium precursor species, and optimize thermal transport to the powder.

PowerCeram™ Saggers: Our next-generation PowerCeram™ saggers, made from advanced silicon carbide, enhance kiln capacity, reduce energy consumption, and extend sagger lifecycle. These saggers are customizable to meet specific heat treatment challenges and come in various shapes and sizes to suit different process conditions.

Contact Us for More Information

Optimize Your Kiln Performance: To maintain the efficiency of your roller hearth kilns and ensure the effective production of lithium-ion battery cathode powders, contact Saint-Gobain Performance Ceramics & Refractories. Our team can help you choose the best equipment for your specific needs.

FAQ

What are saggers and rollers used for in roller hearth kilns?

Saggers in roller hearth kilns serve as containers for powder materials, protecting against contamination and ensuring proper sintering. Rollers are used to transport the saggers within the kiln.

What benefits do rollers and saggers offer in producing lithium-ion battery cathode powders?

Saggers and rollers enhance control over the conditions necessary for efficient calcination and sintering. Saggers contain the powders during high-temperature processes, while rollers ensure consistent transportation of the saggers.

What materials are used to create saggers and rollers at Saint-Gobain Refractories?

Saint-Gobain Refractories uses materials such as silicon carbide, Alundum®, Annamullit®, and Mullfrax® for saggers. For rollers, materials include Hexoloy® SE, Silit® SK, and Crystar®. Explore our brochures for more details on our material offerings.