Silit® SKD Reaction Bonded Silicon Infiltrated SiC

Material Properties

Silit® is a silicon infiltrated Silicon Carbide material, consisting of 85% SiC and 15% Si metal.

Silit® products are branded as Silit® SK or Silit® SKD depending on the manufacturing process. Both are made by Reaction Bonding and Siliconizing of SiC, Carbon and Si metal.

Key benefits of Silit® SKD

Silit® products are lighter than Sintered SiC, yet offer high thermal conductivity, little to no apparent porosity, high mechanical strength, oxidation resistance and maximum service temperature of 1,350°C. Silit® products can be made in large sizes and complex shapes, with excellent as-fired dimensional accuracy.

Silit® SKD Specifications

| Properties | Units | Typical values | |

| SiC | % | 85 | |

| Maximum Use Temperature | °C | 1,380 | |

| Flexual Strength | @ Room Temp | MPa | 260 |

| Density | g / cm³ | 3 | |

| Apparent Porosity | % | 0 | |

| Modulus of Elasticity | GPa | 340 | |

| Coefficient of Thermal Expansion | 10-6 / °C | 4.5 | |

| Thermal Conductivity | @ 1,000°C | W / mK | 35 |

Related products

Ceramic Radiant Tube

Discover Saint-Gobain Performance Ceramics & Refractories’ extensive range of solutions for high temperature heat treatment applications.

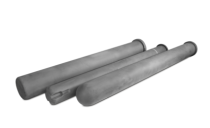

Rollers

Saint-Gobain Performance Ceramics and Refractories' rollers offer distinctive mechanical, thermal & corrosion resistant characteristics.

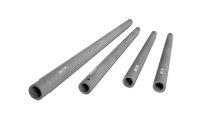

Beams

Discover Saint-Gobain Performance Ceramics and Refractories beams products family to provide structural support for numerous high temperature kiln and...

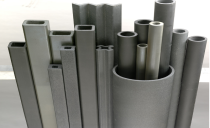

Tubes

Saint-Gobain-Performance Ceramics and Refractories' wide range of tube sizes and features that possess high temperature stability, high thermal...

Plates

Saint-Gobain Performance Ceramics and Refractories offers a wide range of materials and sizes for plates or batts to make the right product selection for...

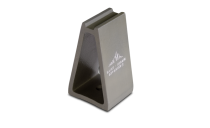

Supports

Discover Saint-Gobain Performance Ceramics & Refractories’ range of customized kiln furniture system, including posts, beams, setters, and supports.

Related content

Nozzles

Hexoloy® Silicon Carbide and Norbide® Boron Carbide ceramics deliver excellent wear and corrosion resistance, maintaining nozzle shape and flow consistency...

Wear Resistant Technologies

Saint-Gobain Performance Ceramics and Refractories have developed a range of wear resistant technologies using alumina oxides (Al2O3 and ZTA) as well as...

Metrology Ceramics for CMM & Motion Control Equipment

Advancer® NSiC and Silit® SKD SiSiC products -- ceramic solutions for high accuracy CMM and Motion Control equipment.