Secondary Copper

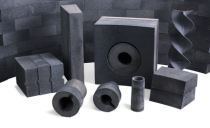

Saint-Gobain Performance Ceramics & Refractories has introduced a third generation of silicon carbide (SiC) refractories designed to effectively protect copper furnaces.

Dedicated R&D teams have developed high performance materials that offer an industry-leading service life. In the field, experienced engineers apply their design expertise to deliver refractory systems that enhance furnace performance, reliability and service life.

Solution By Equipment

Click on your equipment to find more:

- Shaft Furnace

- Holding Furnace

- Launders

- Tap Hole System

Holding Furnace

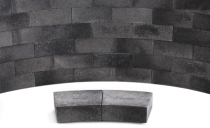

The holding furnace is an essential part of the continuous casting process. Its highly specialized design requires the use of custom refractory shapes such as inlet and outlet ports, skim and vent doors and burners.

The hot face material is composed of Saint-Gobain Performance Ceramics & Refractories’ Cryston® CU bonded SiC, ensuring extended service life.