Foundry

Saint-Gobain Performance Ceramics & Refractories (PCR) delivers cutting-edge refractory solutions tailored to the demanding requirements of both ferrous and non-ferrous foundries. Backed by decades of industry expertise, NORTON® product portfolio—including for example NORVIBE™ dry vibrated monolithics, NORCAST™ castables, and NORRAM™ ramming mixes and more.

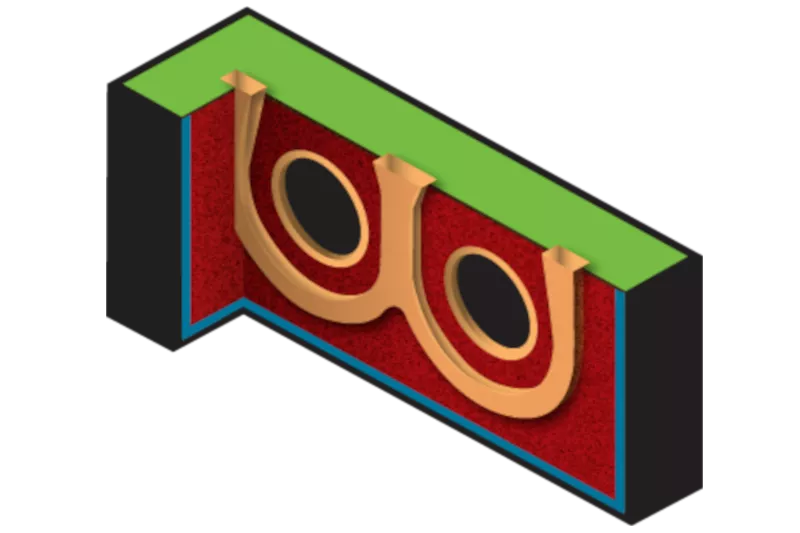

This product range offers reliable performance across a wide range of high-temperature applications such as coreless induction furnaces, ladles and pouring furnaces.

Engineered to withstand extreme operating conditions, our refractory materials provide outstanding corrosion resistance, mechanical integrity, and long service life, supporting greater process stability and metallurgical purity.

Beyond materials, Saint-Gobain PCR provides a comprehensive service offering, including refractory design, installation and repair, supervision, and performance auditing. Our expert teams collaborate closely with customers to optimize furnace performance, reduce energy consumption, minimize emissions, and support sustainable manufacturing practices, including waste recycling and EHS-compliant solutions.

Solution By Equipment

Click on your equipment to find more:

Inductor

FAQ

Is support available around the installation and management of refractory products?

Saint-Gobain Performance Ceramics & Refractories’ skilled and experienced teams are on hand to provide worldwide refractory installation and supervision services, including drying/heating or management of turnkey projects.

Which high alumina refractory mixes should be used for inductor lining when looking to optimize inductor lifetime?

The NORVIBE™ and NORCAST® range has been specifically designed to be installed around the inductor. The NORVIBE™ A 122, NORCAST® K 1031 products offer optimized compaction and controlled sintering properties, efficiently protecting the inductor and reducing metal infiltration. In addition, they are easy to install and use the highest quality raw materials to ensure consistent performance while extending furnace campaign life.