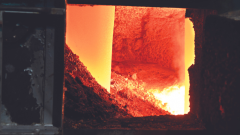

Why Use Fused Cast Refractories for Reheating Furnaces?

Reheating is a key thermal process in steelmaking. It's used to heat stock (billets, blooms, slabs, etc.) to temperatures approaching 1200°C before entering the rolling mill. This reheating process occurs continuously in both electric and oxygen-based steelmaking systems. Stock is heated via convection and radiation within the reheating furnace and then is discharged into the hot rolling mill. Central to the efficiency of these systems is the refractory lining. Any industrial furnace, especially those used in steelmaking, requires advanced insulating materials like electrofused refractories to maximize heat transfer to the product and limit thermal losses. This specificity is crucial in the context of steelmaking, which is characterized by tight margins and strict Environmental, Social, and Governance (ESG) goals.

Fused Cast Refractories Conception

Fused cast refractories are manufactured by melting specific raw material compositions in electric furnaces at elevated temperatures. Their hallmark traits include exceptional refractoriness, formidable resistance to thermal spalling, and a robust defense against chemical attack. A notable advantage is their ease of deslagging, both hot and cold, attributed to the feeble adherence of oxide layers, ensuring the furnace refractory remains undamaged.

So, why use fused cast refractories for reheating furnaces? The answer lies in their unparalleled attributes that promise efficiency and longevity. Let's explore how Magmalox®, a fused cast refractory, bring unique advantages to this domain.

Benefits of Fused Cast Refractory

#1 Resistance to Corrosion, Erosion, and Mechanical Stress

On the other hand, Magmalox® products, used extensively in both pusher and walking-hearth furnaces, are designed to withstand severe wear and tear. Their application results in record tonnage of reheated slab or billet per campaign and improved surface quality of reheated products.

#2 Stability in Harsh Chemical Environments

Magmalox® products, recommended for a range of furnace applications, exhibit outstanding resistance to erosion and corrosion.

#3 Thermal Conductivity and Shock Resistance

Magmalox®, with its diverse range like RN, DR, 550, and 555, offers varying thermal conductivities, ranging from 3.1 W/m.K to 9.2 W/m.K at 1250°C. This ensures that steelmakers can choose the right product based on their specific needs.

#4 Optimizing Furnace Behaviour

Magmalox® products, derived from extensive research and experience, are tailored to optimize the behavior of different furnace areas. This not only balances wear across the furnace but also significantly extends the campaign life.

Looking for Fused Cast Refractories?

At Saint-Gobain Performance Ceramics & Refractories (PCR), we pride ourselves on our legacy of innovation and expertise in the realm of refractory solutions. Our Magmalox® products are testaments to our commitment to excellence, offering unparalleled performance in reheating furnace hearths. With over six decades of experience, we understand the intricacies of steelmaking and the pivotal role refractories play in optimizing furnace operations.

As the industry evolves, so do our solutions, ensuring that our partners always stay ahead of the curve. We invite you to delve deeper into the world of advanced refractories and discover how, together, we can elevate your furnace operations to new heights. Trust in Saint-Gobain PCR to be your partner in achieving sustainable and efficient steel production.

Related Content

Reheating Furnace

Reheating furnace equipment help steelmakers to optimize the behavior of each area of the furnace, to balance wear and to substantially increase campaign...

Saint-Gobain Performance Ceramics and Refractories now benefits from EPD®...

Our SEPR Italia plant, known for producing refractory blocks for glass furnaces and iron and steel markets, obtained EPD certification for its Magmalox®...