By the end of 2023, our team supervised part of the blast furnace refractory installation at ArcelorMittal BFA in Belgium, in which our refractories played a key role.

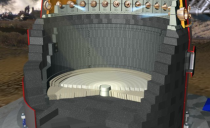

Relining of blast furnace #A at ArcelorMittal Gent, Belgium

After supplying full scope hearth materials (carbon/graphite and refractories) for the relining of blast furnace #B in 2020, the Saint-Gobain Performance Ceramics & Refractories team has once again provided the essential refractories for the relining of blast furnace #A at ArcelorMittal GENT in Belgium in 2023. The refractories engineered in close communication with customer and manufactured at our facilities in India, add additional safety, longer life and specific properties that are required for each area of supply and complement the overall concept of the blast furnace lining: Refractories for the pad layers and the tuyere belt.

The lower and upper ceramic pad layers

As part of our solution for the upper pad layer, bricks were supplied in alumina quality, together with the accompanying mortars and castables.

The lower and upper tuyere belt block

This technical part is subject to harsh conditions, as it allows and protects the hot air intakes. The supplied materials must provide excellent thermal and mechanical resistance, along with resistance to corrosion during the iron ore reduction process.

Depending on the required properties of the two different tuyere belt locations, the lower tuyere blocks feature a high Alumina precast block in Monocoral quality. While the upper tuyere block is delivered as pre-assembled and clued block in Sicanit TB (SiAlON bond SiC) quality and sourced from Halol, one of our two Indian manufacturing facilities. The installation process uses a custom-made and CE certified lifting and installation device.

Choosing Sicanit TB for the upper part provides greater resistance to abrasion and corrosion. This robust, conductive material can withstand arising operating temperatures.

Integrated expertise in R&D, design and engineering

To enhance blast furnace performance, our team of dedicated and highly qualified engineers proposed, based on specifications, the design of shapes and the selection of materials. They subsequently developed plans for the refractories, which were later installed on site, relying on thermal calculations performed using Ansys.

With the support of our R&D centers and our team specialized in blast furnace applications, we addressed the aggressive constraints of this environment and developed materials with exceptional resistance. In the case of the tuyere belt, the choice of Sicanit TB aimed to improve corrosion resistance, thereby increasing the lifetime of the blast furnace.