INTRADEL was founded in 1979 as an intercity waste treatment facility in Herstal, Belgium. The plant UVELIA was built in 2008 on the site of INTRADEL to valorize household waste into electrical and heat energy through combustion. It was commissioned in 2009 and has been operated non-stop since then, except for annual maintenance pauses. In 2019, it produced 225,000 MWh while consuming 378,000 tons of waste.

As a partner of Uvelia and their installer, Saint-Gobain supports its drive to improve the quality and duration of combustion campaigns through continuous innovation and technical feedback.

Working Conditions

- Our microstructure with bigger crystals improves resistance to corrosion and oxidation.

- Low volume expansion, due to the low oxidation is very important for the application. The expansion joints remain intact and the material can be used for an even longer period of time.

- The mechanical strenght remains constant in contrast to oxide bonded SiC, where mechanical strenght decreases with increasing temperature.

The Challenge

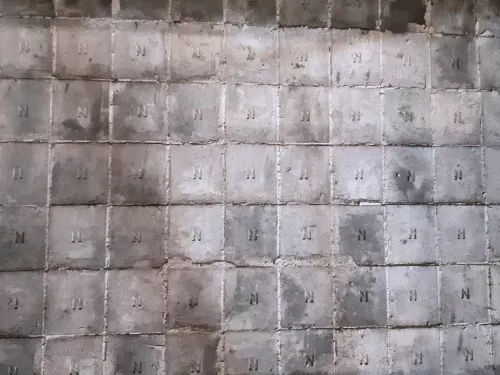

This led to high replacement costs, frequent shutdowns, both greater than planned, increasing the yearly budget over expectations. Tiles from different manufacturers in OBSIC and similar material were tried during the following years. However, there was no significant improvement in lifetime.

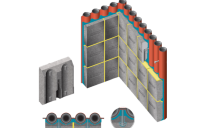

Our solution, Refrax® PLUS Tiles

In 2015, Refrax® Plus from Saint-Gobain were tested on a few square meters of the first pass. These fulfilled the trial’s target and they replaced the original tiles to reach the complete half of the pass in 2021.

The plant has continuously increased the amount of Refrax® Plus tiles as the life expectancy met the needs of the operation in the combustion conditions experienced on site.

The current maintenance manager has found the perfect material, storing large quantities of tiles for future maintenance and potential expansion of Refrax® Plus tiles in other areas.

Refrax® Plus Tiles Benefits