Filtration

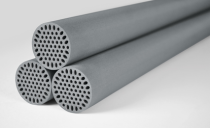

Saint-Gobain Performance Ceramics & Refractories have been providing unique and high added value silicon carbide-based solutions for decades, including the first-to-market recrystallized silicon carbide (R-SiC) product. This outstanding ceramic forms the basis of our Crystar® filtration technology.

Crystar® FT is designed for liquid and air purity, security, and sustainability. The demands of filtration have changed dramatically over the years, as a growing global population forces industries to adopt more demanding processing capabilities to satisfy the needs of global sustainability efforts.

Saint-Gobain designs, manufactures and distributes materials and solutions which are key ingredients in the well being of each of us and the future of all. They provide comfort, performance and safety while addressing the challenges of sustainable construction, resource efficiency and climate change.

With Crystar® FT membranes and filters, Saint-Gobain is committed to improving the sustainability of sectors as diverse as water/wastewater, industrial processes & life sciences, and recreational water, with new and innovative products.

We aim to make sustainability a driving force for every liquid filtration and air purification sector. Crystar® FT technology provides microfiltration of leading efficiency, with consistent retention, excellent filtrate quality at high fluxes, and operation with low consumption of energy, water and chemicals.

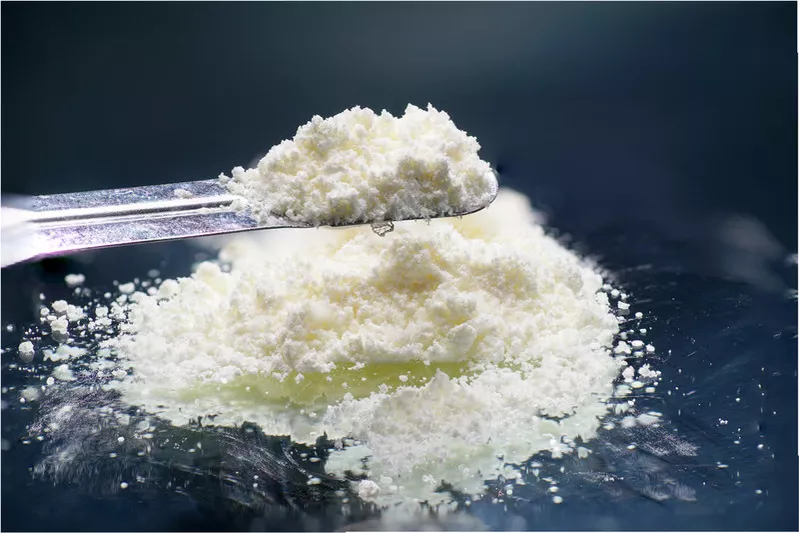

Powder manufacturing & Recovery

An Energy-Efficient Process with Crystar® FT

Crystar® ceramic membranes have successfully been used as an alternative to slurry evaporation in the manufacturing and recovery of high-value powders. These powders or powder slurries can usually be obtained through evaporation; a process that consumes large amounts of energy and water. Crystar® microfiltration represents a massive improvement in terms of efficiency, reduction in energy of powder processing, and concentration factors that can eliminate the need for more energy demanding evaporation systems.

In these critical powder processing operations Saint-Gobain’s Crystar® crossflow membranes offer the following benefits:

- high permeate fluxes for a fast and efficient powder concentration process,

- sharp selectivity thanks to the well-engineered and controlled layer of recrystallized silicon carbide,

- the possibility to work in harsh environments (solvents for instance) thanks to outstanding chemical resistance of Crystar® ceramic membranes,

- long lifetime thanks to the superior abrasion resistance of silicon carbide and the special capping technology used in Crystar® crossflow membranes.