Specialty Ceramics

High-performance advanced ceramics for extreme conditions

Saint-Gobain Performance Ceramics & Refractories offers advanced specialty ceramics products, consisting of silicon carbide, silicon nitride, Alumina and Boron Carbide materials, designed to perform reliably in the harshest conditions. These engineered solutions provide exceptional thermal stability, corrosion resistance, and mechanical strength, making them ideal for high-temperature reactors, chemically aggressive processes, precision metrology, mechanical seals, thermocouple protection & gas sensors, labware operations, and semiconductor manufacturing equipment. Focused on durability and efficiency, Saint-Gobain’s solutions help critical industries improve reliability, minimize maintenance, and optimize operational performance.

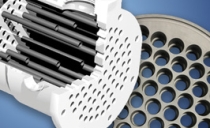

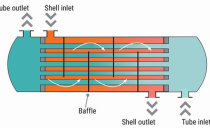

Shell & Tube Heat Exchangers

Sintered Silicon Carbide Tubes and Tube-sheets

Hexoloy® SiC combines thermal conductivity with corrosion resistance to extend the life and efficiency of heat exchanger tubes exposed to harsh chemicals, pressure, and thermal cycling.

For more than 30 years, Hexoloy® SE silicon carbide tubes have provided the most reliable and preferred choice for shell & tube heat exchangers used in fine and specialty chemicals. This success is based on virtually universal corrosion resistance, high thermal conductivity, extremely high hardness and mechanical strength of Hexoloy®.

Hexoloy® SE tubes are available in 12.7 mm, 14 mm, and 19 mm outside diameter and lengths up to 5 m. Each tube is proof tested up to 186 bars (2700 psi). Hexoloy® SA SiC tube sheets are also available as per OEM design.

Saint Gobain Ceramics has sold more than one million meter of heat exchanger tubes.

Corrosion Resistance of Different Materials Against Chemicals

| Test Environment* | Corrosive Weight Loss (mg/cm2 yr) | ||||

| Conc. Reagent (Wt%) | Temp. (°C) |

Hexoloy® SA (No Free SiC) |

Reaction Bonded SiC (12% SiC) |

Tungster Carbide (6% Co) |

Aluminium Oxide (99%) |

| 98% H2SO4 | 100 | 1.8 | 55.0 | >1,000 | >65.0 |

| 50% NaOH | 100 | 2.6 | >1,000 | 5.0 | 75.0 |

| 53% HF | 25 | <0.2 | 7.9 | 8.0 | 20.0 |

| 85% H3PO4 | 100 | <0.2 | 0.5 | >1,000 | 7.0 |

| 45% KOH | 100 | <0.2 | >1,000 | 3.0 | 60.0 |

| 25% HCI | 70 | <0.2 | 0.9 | 85.0 | 72.0 |

| 10% HF plus 57% HNO3 | 25 | <0.2 | >1,000 | >1,000 | 16.0 |

*Test Time: 125 to 300 hours of submersive testing, continuously stirred.

FAQ

Does Saint Gobain design and build heat exchangers?

No. Saint Gobain works with heat exchanger OEMs worldwide.

How do Silicon Carbide tubes perform against fouling liquids?

Silicon Carbide tubes are known to offer greater resistance to fouling.

What are the key benefits of using Silicon Carbide Tubes?

Hexoloy® Silicon carbide is essentially inert to a wide range of corrosive chemicals, including strong acids and caustics, up to 200°C. Most alternatives, such as graphite, metals, alloys, introduce contamination over time from corrosion. Other key benefits include high heat transfer, superior mechanical strength, and low thermal expansion.