Total Burner Solutions for Energy and Carbon Reduction

Thermal manufacturing process managers must continue to improve efficiency, achieve higher productivity, reduce emissions and overall energy use and keep equipment running as long as possible.

Saint-Gobain Performance Ceramics & Refractories collaborates with customers and partners to continually innovate and engineer products to meet customer needs around ongoing improvement and efficiency.

Single ended radiant tubes, U-tube and W-tubes each utilize enhanced design solutions and carefully selected materials to ensure performance and efficiency. Silit® ceramic radiant tubes, recuperators, flame tubes, and combustors are all established, proven and time-tested designs.

Saint-Gobain Performance Ceramics & Refractories’ total burner solutions utilize additive manufactured advanced silicon carbide (Amasic-3D®) combined with twisted channel HeatCor™, twisted tape SpyroCor®, PyroCor™, and NOxBuster™ technology to achieve best-in-class thermal and emissions performance.

Solution By Radiant Tubes

Click on your radiant tube to find more:

W-TUBE

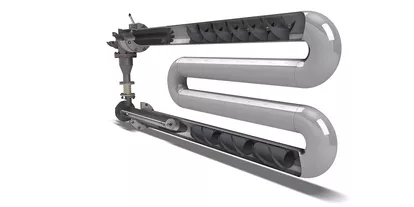

Radiant W-tube combustion systems are an industry standard for the indirect heating of metals in a protective atmosphere. The W-tube, modular burner and plug-in type recuperator typically operate at temperatures up to 1,000°C and efficiencies of 70%.

Leveraging the power and reliability of Saint-Gobain Performance Ceramics & Refractories’ twisted channel HeatCor™ recuperator, twisted tape PyroCor™ flame tube, SpyroCor® radiant tube insert and NOxBuster® internal exhaust gas recirculatory can enable increased throughput, energy savings, reduced emissions and lower maintenance frequencies.

Features and Benefits

- Made of robust silicon carbide

- Operating temperatures up to 1,350°C

- Long service life

- Thin-wall twisted geometries improve heat transfer

- Optimized efficiency Improved temperature uniformity

- Thermal shock resistant microstructure

- Effective thermal cycling in high temperature environments

- Computationally modeled thermal designs optimize NOx and carbon reduction within the radiant tube

| Radiant Tube System | ||||

| Single Ended Tube | U-Tube | W-Tube | Brand | |

| Silit Products |

1,350°C thermal shock resistant |

1,350°C thermal shock resistant |

Amasic-3D® Products | |

| ...Improvement | ||||

| Ceramic Radiant Tube | 2x heat release | 5 - 15% throughput, energy, emmissions | SpyroCor® | |

| Recuperator | 70 - 75% efficient | 75 - 85% efficient | HeatCor™ | |

| Flame Tube | 2x life | 10 - 25% uniformity | PyroCor™ | |

| Combustor | finned surface | 10 - 50% NOx Reduction | NOx Buster® | |

FAQ

How does PyroCor™ work?

PyroCor™ utilizes a specialized design and variable twists to optimize temperature uniformity in the radiant tube.

What are the material properties of Silit® and Amasic-3D™?

These infiltrated SiSiC high performance, non-porous ceramic materials can accommodate application temperatures of 1,380°C. They also offer excellent thermal strength properties.

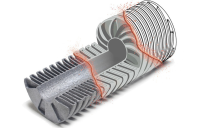

What is a twisted channel HeatCor™?

The HeatCor™ is a new heat exchanger design that incorporates a higher surface area twist channel versus traditional fins and bumps. This increased surface area allows for an increase in effectiveness of over 10%.

What is the minimum wall thickness possible with Silit® and Amasic-3D™?

The thinnest possible wall thickness is approximately 4 mm with Silit® and 2 mm with Amasic-3D™.