Wear Resistant Technologies

Saint-Gobain Performance Ceramics & Refractories’ innovative Wear Resistance Technologies business unit, can manufacture a wide range of different high grade ceramic materials.

Wear Resistance Technologies can customize products and soliutions according to customers’ abrasion, erosion and corrosion needs. Our core objective is to ensure the optimum performance, efficiency and service life of customers’ equipment and systems; while aligning our values on sustaibability and carbon free goals

.

Solution By Equipment

Click on your equipment to find more:

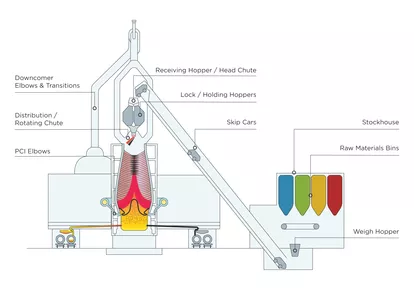

Blast Furnace Charging Systems

Raw material input is one of the most important control variables for optimized blast furnace operation. Both the accuracy and reproducibility of the charging process and the reliability and ease of maintenance of the charging equipment are critical.

Saint-Gobain Performance Ceramics & Refractories helps customers to achieve these goals by providing custom, wear-resistant ceramic solutions for blast furnace areas outside of the bosh, stack and hearth. Saint-Gobain Performance Ceramics & Refractories’ wear-resistant technologies can be used in a range of applications, including:

- Receiving hopper

- Revolving hopper

- Lock and holding hoppers

- Diverters

- Charge end sockets

- Discharge funnels

- Conical sockets

- Equalizing relief piping and uptakes

Sintered Ceramic Solutions for Blast Furnaces

| Alpha Al2O3 | Zirconia Toughned Alumina | |

| Durafrax® | Durastrike® ZTA | |

| Sliding Abrasion | +++ | ++++ |

| Erosion | +++ | ++++ |

| Impact | + | +++ |

| Corrosion Resistance | ++ | ++ |

| Thermal Shock | + | ++ |

| Thermal Insulation | + | + |

| Electrical Insulation | ++++ | +++ |

| Nitride Bonded SiC | Reaction Bonded SiC | Sintered Alpha SiC | ||||||||

| Cryston® | Cryston® TW | Cast Refrax® 20 | Refrax® 20 | Norfrax® RB | Silit® SKD | HAMMERfrax® | Hexoloy® | |||

| Sliding Abrasion | + | ++ | + | + | +++ | +++ | ++++ | ++++ | ||

| Erosion | + | + | + | + | ++ | ++ | +++ | ++++ | ||

| Impact | ++ | + | + | + | + | + | ++ | + | ||

| Corrosion Resistance | ++ | ++ | ++ | ++ | +++ | +++ | ++ | ++++ | ||

| Thermal Shock | + | ++ | ++ | ++ | ++ | ++ | ++ | ++ | ||

| Thermal Insulation | ++ | ++ | ++ | +++ | + | + | + | + | ||

| Electrical Insulation | NA | NA | NA | NA | NA | NA | NA | NA | ||

| Fused Cast AZS | Zirconia Toughned Alumina | |

| ZAC - Corguard® | Durastrike® ZTA | |

| Sliding Abrasion | ++ | ++++ |

| Erosion | ++ | ++++ |

| Impact | +++ | +++ |

| Corrosion Resistance | ++ | ++ |

| Thermal Shock | ++ | ++ |

| Thermal Insulation | ++ | + |

| Electrical Insulation | ++ | +++ |

| Silicon Carbide | Aluminium Oxide | |

| Wearfrax® RS58 | Wearfrax® RA57 | |

| Sliding Abrasion | + | + |

| Erosion | + | + |

| Impact | + | + |

| Corrosion Resistance | + | + |

| Thermal Shock | ++ | + |

| Thermal Insulation | ++ | + |

| Electrical Insulation | NA | NA |

Documents

FAQ

How do ceramics perform against chrome carbide overlay in terms of wear-resistance?

Ceramics have been found to perform 3-5 times better than chrome carbide overlay in terms of wear resistance, depending on the application.

How does the use of sinter in blast furnace operations affect the use of ceramics?

Sinter is a very dense, abrasive material that requires special attention when designing ceramic solutions. Saint-Gobain Performance Ceramics & Refractories’ engineers have successfully designed and installed numerous ceramic lining systems for blast furnaces utilizing sinter.

How much does it cost to install ceramics?

Installation cost varies depending on specific customer requirements, equipment, and operating conditions, but customers have reported that overall installation costs are similar to the cost of installing AR steel wear panels.

The total cost of ownership of ceramics is considerably less over the life of the installation versus traditional lining materials.