High Performance Materials: What is Tap Hole Clay?

Higher rates of deterioration are often correlated to greater production rates. This poses unique profitability challenges where high throughput could translate to poor life cycle costs.

A Brief Introduction to Tap Hole Clay

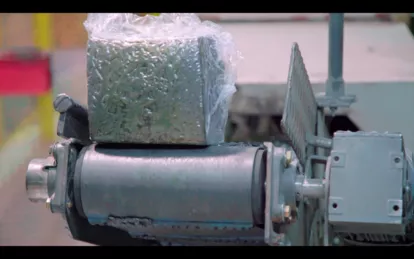

Tap hole mixtures are sophisticated solutions composed of multiple high performance raw materials. These materials work in tandem to produce a unique formulation with high corrosion- and erosion-resistant properties, excellent adhesiveness, and adequate plasticity across the entire blast furnace operating temperature range.

Typical tap hole clay products protect the ceramic hearth by forming a “mushroom” over time. The mix is pushed into the tap hole after each casting, gradually accumulating close to the inner walls and forming a stable ceramic coating. This mushroom protects the hearth from damage by pig iron or slag, and it is sequentially replaced by new tap hole clay in-between castings. Using poor quality clay can be detrimental as more material is needed to achieve the desired effect. This could lead to higher costs and early maintenance of blast furnace hearth.

Designing High Performance Tap Hole Clay

Any changes on tap hole clay should be designed based on three key performance concepts: High resistance to corrosion and erosion to ensure long casting durations and uniform casting rates; good adhesion to the blast furnace inner wall to promote stability; and necessary plasticity to facilitate efficient pushing/drilling.

At Saint-Gobain High Performance Ceramics and Refractories, we have developed a novel tap hole mix for blast furnaces that innovatively maximises the protection feature by homing in on each of these design pillars. Our high performance materials are easy to drill, inherently resistant to typical corrosion mechanisms, have excellent plasticity, and are highly adhesive across broad temperature regimes.

High-Performance Taphole Clay: A Key for Blast Furnace Hearth Protection and a Tool for Cost Reduction

Would you like to learn more? Read our technical article on our high performance tap hole clay materials. Or, contact a member of the Siant-Gobain team.

Related Content

Tap Hole Clay

Discover Saint-Gobain Performance Ceramics & Refractories’ state-of-the art solutions for safe and efficient pig iron production.

Blast Furnaces Refractories

Descubra a gama de soluções refractárias da Saint-Gobain Performance Ceramics & Refractories para aumentar a vida útil dos altos-fornos.