Using Silicon Carbide Components for Wafer Handling & Inspection

Silicon carbide (SiC) is a hard chemical compound consisting of silicon and carbon, and it exists in around 250 different crystalline forms. The most common polymorph is "α" -SiC, which has a hexagonal crystal structure. Alongside very high hardness, silicon carbide exhibits several characteristics which make it a desirable engineering material.

In particular, it is highly chemically inert, and it doesn’t melt at any known temperature: instead, it sublimates from a solid into a gas at the very high temperature of 2,800°C, making it extremely useful for bearings and furnace components.

Since it was first manufactured in the late 19th century, silicon carbide has been adapted to a huge range of applications. It’s still used on a large scale as an abrasive, particularly in machining processes such as grinding and sandblasting. Grains of silicon carbide can also be sintered together to form incredibly hard and resilient ceramics, which are typically used for hard-wearing applications such as car brakes and bulletproof vests. Silicon carbide is also a semiconductor, earning it a range of applications in power electronics, notably in the production of electric vehicle (EV) powertrains.

Applications of Silicon Carbide in Semiconductor Manufacturing

As the critical dimensions of semiconductor devices continue to decrease, their sensitivity increases. Modern semiconductor manufacturing plants must take care to keep semiconductors in a completely inert environment and protect them from any possible form of corrosion or chemical attack.

Silicon carbide is an ideal material for semiconductor applications thanks to its extreme chemical inertness. For example, Hexoloy® silicon carbide from Saint-Gobain offers extremely high chemical purity (>98%) with no free silicon, alongside superior oxidation resistance even at high temperatures. This makes it ideal for applications in wafer handling and inspection, where eliminating contaminants and preventing unwanted chemical reactions is critical.

Saint-Gobain Silicon Carbide Products for Semiconductor Applications

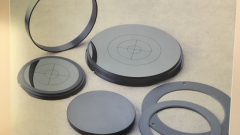

Hexoloy® SA SiC is a pressure-less sintered form of alpha silicon carbide with extremely high density (over 98% of the theoretical maximum). Offering a very fine grain structure (4-10 microns) and containing zero free silicon, it is also highly resistant to wear from rotation or sliding forces. Hexoloy® SA is ideally suited to semiconductor applications including:

• Wafer Grinding & Polishing Plates

• Discs for Vacuum Chucks

• Wafer Clamps

• Wafer Carriers

• Reactor Tubes for Thermal Oxidation

Other Hexoloy® products with semiconductor applications include the electrically conductive Hexoloy® SG for sputtering targets, and Hexoloy® SE for closed-one-end (COE) thermocouple protection tubes.

Additionally, our siliconized SiC product line Silit® exploits the light weight and high stiffness of silicon carbide for absolute precision and high speeds in industrial metrology equipment. Our Silit® Beams set a high performance benchmark for construction beams used in Z axis, bridge, and air bearing stages.

Saint-Gobain is a world leader in the production of high-performance refractory materials for all applications. Alongside our existing line of silicon carbide products, we offer our expertise to customers in the form of unique and novel material solutions tailored to suit the most challenging applications. To find out how Saint-Gobain can help your engineering application, get in touch with us today to discuss the co-development of a new material.

Related Content

Specialty Ceramics

Saint-Gobain Performance Ceramics & Refractories’ extensive range of specialty ceramic products – ideal for use in the harsh environments typical in broad...

Hexoloy SE SiC Material

Discover the benefits of Saint-Gobain Performance Ceramics & Refractories’ Hexoloy® SE silicon carbide material.

Hexoloy SG SiC Material

Discover the benefits of Saint-Gobain Performance Ceramics & Refractories’ Hexoloy® SG silicon carbide material.

Hexoloy SA SiC Material

Discover the benefits of Saint-Gobain Performance Ceramics & Refractories’ Hexoloy® SA silicon carbide material.