LO-MASS® Kiln Furniture from Saint-Gobain

Saint-Gobain High-Performance Ceramics & Refractories pioneers material innovation in challenging manufacturing environments. With decades of experience servicing a wide range of industrial markets, from rugged mining applications to precise high technology sectors, we have successfully curated a catalog of performance ceramics and refractories to suit any industrial objective. Among our core competencies is the ability to design and develop remarkably stable kiln furniture for extreme thermal processes.

In this article, we will explore the benefits and features of our proprietary LO-MASS® kiln furniture in more depth.

What is Kiln Furniture?

Typical kiln furniture components include refractory ceramic beams, lug posts, plates, saggers, setters, tables, tile cranks, and so on. However, these largely depend on furnace geometry. Roller hearths, for example, require high-temperature mechanical conveyors to continuously feed workpieces through a tunnel chamber with several heating zones.

These are used throughout thermal processes, which means they are routinely fired at extremely high temperatures, thus are subjected to severe thermochemical stress. Consequently, kiln furniture may need to be replaced regularly due to rapid component degradation. This represents a significant ongoing cost. Advanced silicon carbide products of today are engineered to mitigate this issue, taking standard components from mere hundreds of cycles to thousands.

Additional costs are incurred due to over-utilization of space in the heating chamber by heavy ceramics like cordierite-based products. Kiln furniture increases the rate of energy consumption in routine thermal processing, which impacts efficiency and ultimately affects the plant’s bottom line.

Improving Productivity with LO-MASS® Kiln Furniture

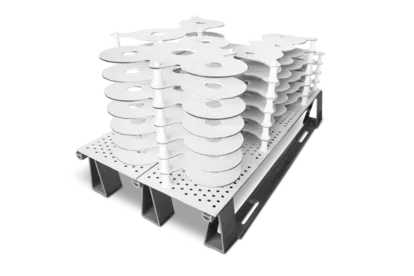

At Saint-Gobain, we strive to enhance the productivity of manufacturing chains and production lines with precision solutions based on the highest quality materials available. Our LO-MASS® kiln furniture is based on advanced silicon carbide, an exceptionally hard ceramic with superb mechanical strength at elevated temperatures. This enables us to generate thinner kiln furniture components for reduced heat capacities, without compromising on service length.

All our LO-MASS® kiln furniture products exhibit high thermal conductivity and low thermal mass which translates to greater efficiency throughout an extended number of use cycles. This enables process engineers to reduce ongoing material expenses due to regular kiln furniture replacements, product defects, and reworks while simultaneously improving thermal efficiency, therefore reaching superior levels of productivity.

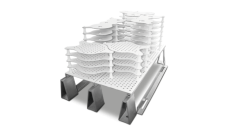

Saint-Gobain application engineers are experienced in custom designing kiln furniture systems for specific applications and automation requirements. LO-MASS® engineered components include setter plates, support posts & stringer beams, post mounting shoes and structural tie systems. Numerous other custom shapes and engineered assemblies are available to provide flexible setting configurations, decreased setup time, as well as system safety & stability.

Simply contact a member of the Saint-Gobain team today to learn more.

Related Content

Systems for Kilns & Furnaces

Discover Saint-Gobain Performance Ceramics & Refractories’ comprehensive range of ceramic products and solutions - designed, developed, and manufactured...

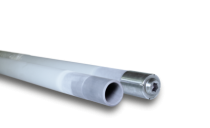

Silicon Carbide Applications: Hot Stamping Rollers

SiC is the leading material for thermal processes which includes ceramic rollers for hot stamping of automobile components.

LO-MASS® Kiln Furniture

Discover Saint-Gobain Performance Ceramics & Refractories’ comprehensive range of solutions and materials for kilns and furnaces, including kiln furniture...