Specialty Ceramics

High-performance advanced ceramics for extreme conditions

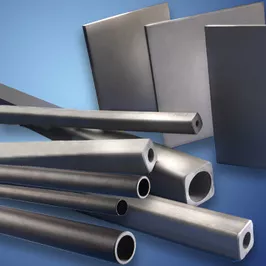

Saint-Gobain Performance Ceramics & Refractories offers advanced specialty ceramics products, consisting of silicon carbide, silicon nitride, Alumina and Boron Carbide materials, designed to perform reliably in the harshest conditions. These engineered solutions provide exceptional thermal stability, corrosion resistance, and mechanical strength, making them ideal for high-temperature reactors, chemically aggressive processes, precision metrology, mechanical seals, thermocouple protection & gas sensors, labware operations, and semiconductor manufacturing equipment. Focused on durability and efficiency, Saint-Gobain’s solutions help critical industries improve reliability, minimize maintenance, and optimize operational performance.

Thermal Processing

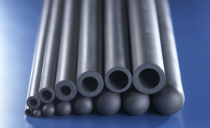

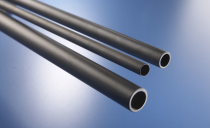

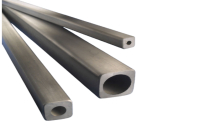

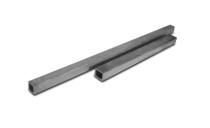

Structural Components for Kilns and Furnaces

Advancer®, N-Durance®, and Refrax® 20E Nitride bonded SiC are used to make furnace components with strong resistance to thermal cycling, oxidation, and mechanical stress.

Saint-Gobain Performance Ceramics & Refractories’ thermal processing products include a range of reliable, high performance and cost-effective options.

Hexoloy® SA sintered silicon carbide, Silit® SK SiSiC and Crystar® 2000 Recrystallized SiC products are excellent choices for thermal processing applications, due to their very high thermal conductivity, low thermal expansion, light weight and high strength at high temperatures.

Example applications include:

- Rapid thermal treatment of fibers and crystals

- High temperature analytical equipment (dilatometers and TGA) components

- Structural components for kilns and furnaces

Key Properties Of Sintered Silicon Carbide Material

| Density | Coefficient of Thermal Expansion (x10-6/K) |

Flexural Strength (Mpa) |

Thermal Conductivity (W/m⋅K) |

Elastic Modulus (Gpa) |

|

| Hexoloy® SA (Sintered SiC) | 3.15 | 4.0 | 380 | 125 | 410 |

FAQ

What applications are Crystar® 2000 best suited for?

Crystar® 2000 Recrystallized SiC is an excellent material choice where high thermal shock resistance is required, for example, exposure to a flame. Its load bearing capability is lower than that of Hexoloy® and Silit® SK SiC due to its higher porosity.

Which product offers the most optimal combination of thermal conductivity, high load bearing capability and high chemical stability?

Both Hexoloy® sintered SiC and Silit® SK SiSiC offer these properties. While Silit® SK is limited to operating temperatures of 1,350°C, Hexoloy® performs well at temperatures up to 1,650°C in oxidizing conditions.

Which silicon carbide product is best suited to very precise temperature control in a furnace?

All of Saint-Gobain Performance Ceramics & Refractories’ SiC products allow precise temperature control due to high thermal conductivity. However, it is important to consider other factors such as thermal cycling, environmental chemistry, and mechanical loading.