Systems for Kilns and Furnaces

Saint-Gobain Performance Ceramics & Refractories’ products and solutions for kilns and furnaces are specifically designed and developed to facilitate consistent and long-term performance at high temperatures (up to 1,800°C) and under severe operating conditions.

Solutions are available for all common types of kilns and furnaces across a wide range of industries.

Ceramic Solution By Application

Click on your application to find more:

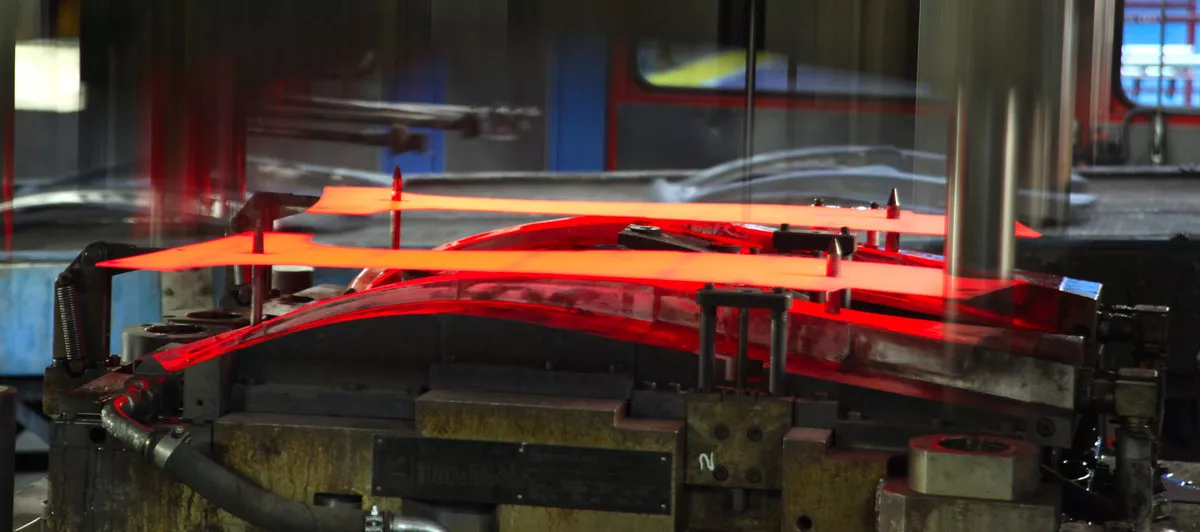

Hot Stamping

Hot stamping - or press hardening - is an established process used in automotive manufacturing to produce high-strength structural parts from thin sheet metal. Hot stamping thermally induces chemical changes in the metal at extremely high temperatures, while forming this into the desired profile.

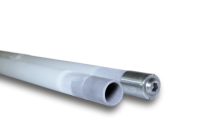

This process enables the fabrication of complex shapes with exceptional strength-to-weight ratios, while virtually eliminating undesired phenomena such as spring back. Best-in-class rollers from Saint-Gobain Performance Ceramics & Refractories deliver unparalleled benefits, including distinctive mechanical, thermal and corrosion resistant characteristics.

Hot stamping rollers are ideal for the challenges associated with steel hardening and hot forming processes, delivering extended service life and reduced maintenance.

FAQ

Can DuraForm® rollers be hot changed?

Yes. DuraForm® rollers’ fixing system allows them to be removed and changed, even when the furnace is under temperature.

Do DuraForm® rollers require maintenance?

Maintenance requirements for DuraForm® rollers are minimal, though periodic cleaning will help extend service life.

How long do DuraForm® Premium rollers last in the hot zone?

DuraForm® Premium rollers have recorded service lives of more than two years, depending on operating conditions.