Hexoloy® SiC Material

Material Properties

The Hexoloy® SiC material was developed in late 1970s. Since that time, Saint-Gobain Performance Ceramics & Refractories’ engineers have successfully commercialized Hexoloy® in a wide range of industrial applications. The unique properties of Hexoloy® SiC allow it to outperform commonly used ceramic materials in harsh operating conditions. Saint-Gobain Performance Ceramics & Refractories’ application engineers are on hand to assist with technical projects, supporting customers in the design of cost effective, high performing products that can meet current and future application requirements.

Manufacturing Hexoloy® Silicon Carbide

How Saint-Gobain Performance Ceramics & Refractories manufactures its precision engineered Hexoloy® sintered silicon carbide products?

Saint-Gobain Performance Ceramics & Refractories pioneered the technology to manufacture a pressureless sintered silicon carbide material - Hexoloy® - in the late 1970s.

Forming Options

Economical forming is determined by shape, quantity volume and tolerances of the final part.

Dry pressing to size is the most economical forming method for volumes of 300 pieces or more, which helps justify the initial expense of tooling designed specifically for each part.

Isostatic pressing is best suited to low volumes and prototype items.

Pre-Sinter (Green) Machining

Machining in the pre-sintered, or green, state is desirable because it allows manufacturing of complex finished shapes without expensive grinding of sintered material.

Green machining is accomplished using conventional processes. Stock removal can be accomplished 15 times faster in the green state than in the sintered state.

Green machining provides parts to tolerances of 0.5% to 1.0% of their final dimensions. Typical green machined surface finishes range between 32 and 64 µin.

Grinding and Finishing

Precision grinding capabilities have been developed to meet the exacting specification requirements required by the automotive, aerospace and nuclear industries.

Saint-Gobain Performance Ceramics & Refractories has the expertise to grind to close tolerances on most shapes (.0005").

Typical ground parts hold finishes of 16 µin or better. When surface finishes are critical in improving friction and wear performance, finishing operations can improve surfaces up to 4 µin providing surface flatness to one helium light band.

Quality Assurance

Saint-Gobain Performance Ceramics & Refractories maintains the highest level of quality by leveraging state-of-the-art, non-destructive evaluation equipment for final quality inspections of internal structures.

These techniques include bulk and surface wave ultrasonics, fluorescent dye penetrant, radiography, acoustic emission, and photomicrography.

HEXOLOY® Grades

Hexoloy SA SiC Material

Hexoloy SA SiC Material

Discover the benefits of Saint-Gobain Performance Ceramics & Refractories’ Hexoloy® SA silicon carbide material.

Hexoloy SE SiC Material

Hexoloy SE SiC Material

Discover the benefits of Saint-Gobain Performance Ceramics & Refractories’ Hexoloy® SE silicon carbide material.

Hexoloy SG SiC Material

Hexoloy SG SiC Material

Discover the benefits of Saint-Gobain Performance Ceramics & Refractories’ Hexoloy® SG silicon carbide material.

Hexoloy SP SiC Material

Hexoloy SP SiC Material

Discover the benefits of Saint-Gobain Performance Ceramics & Refractories’ Hexoloy® SP silicon carbide material.

Related Products

Hexoloy® SE Thermocouple Protection Tube

Discover Saint-Gobain Performance Ceramics & Refractories’ range of products for thermocouple sensor protection.

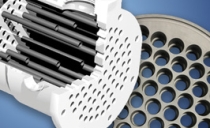

Hexoloy SE Sintered Silicon Carbide Tubes and SA Tube Sheets

Discover Saint-Gobain Performance Ceramics & Refractories’ range of silicon carbide products for shell and tube heat exchangers.

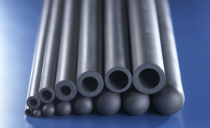

Hexoloy Seal Tubes

Hexoloy® SA sintered silicon carbide seal tubes are available in a wide range of OD and ID combinations. Seal tubes are unground and sold with “as-fired”...

Hexoloy Seal Blanks

Discover Saint-Gobain Performance Ceramics & Refractories’ extensive range of ceramics for mechanical seals.

Hexoloy SiC and Noralide Si3N4 Seals

Discover Saint-Gobain Performance Ceramics & Refractories’ range of engineered and ground faces for mechanical seals.

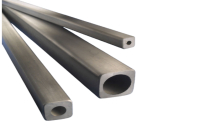

Silicon Carbide Beams

Discover Saint-Gobain Performance Ceramics & Refractories’ extensive range of sintered silicon carbide beams.

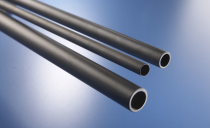

Hexoloy SiC Process Tubes

Discover Saint-Gobain Performance Ceramics & Refractories’ range of process tubes for high temperature processes.

Hexoloy Custom Shapes

Discover Saint-Gobain Performance Ceramics & Refractories’ extensive range of silicon carbide technical ceramics.