How Total Burner Solutions Aid in Heat Recovery

The industrial landscape is continuously evolving, with energy efficiency and carbon emissions reduction at the forefront of its operational priorities. Total burner solutions emerge as a pivotal technology in this regard. These tools offer a comprehensive approach to enhance heat recovery processes.

Total Burner Solutions is a retrofit combination of technologies that provide effective ROIs to customers using combustion systems in thermal manufacturing processes. The solution is highly focused on:

- Reducing energy consumption,

- Reducing carbon generation,

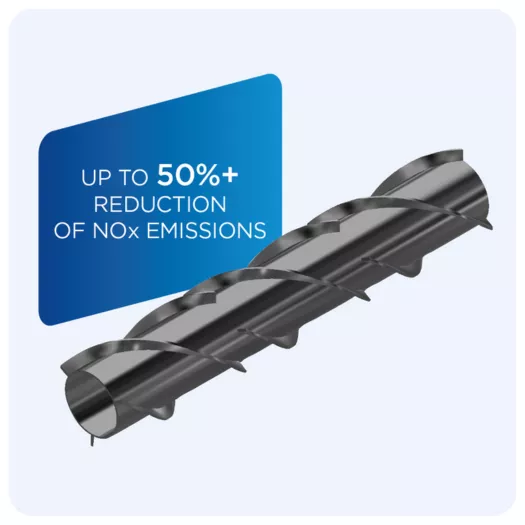

- and Reducing NOx emissions.

Join us as we delve into the mechanisms of total burner solutions. Alongside this, we will consider their benefits and applications across various industrial sectors.

Enhancing Energy Efficiency through Advanced Technologies

Ceramic materials are chosen for their high-temperature resistance and durability. This makes them ideal for the harsh conditions of industrial heating processes. These recuperators facilitate the transfer of heat from the exhaust stream to the incoming combustion air, thereby preheating it and reducing the overall required heat energy.

Additionally, total burner solution systems combine recuperators, inserts and NOx reduction elements to become more efficient while reducing emissions.

NOx reducing elements, on the other hand, are designed to direct the flame in a manner that maximizes a heat exchange and transfer to the material being processed while reducing oxides of nitrogen. Together, these components ensure that the energy from the fuel is utilized to its fullest potential. They also minimize waste and enhance the thermal efficiency of the process. the process.

Carbon Emissions Reduction and Environmental Impact

Furthermore, the improvement in energy efficiency translates into lower operational costs, providing a financial incentive for industries to adopt these solutions.

Applications of Total Burner Solutions Across Diverse Industrial Sectors

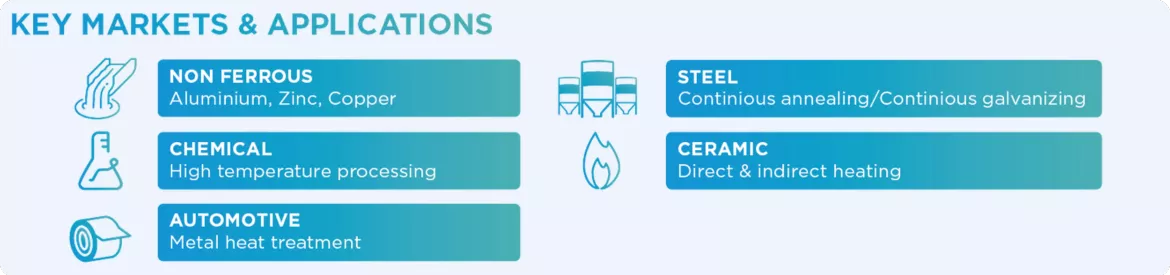

Total burner solutions find applications in a wide array of industrial processes. Notably, their sectors include: Steel and aluminum production, Ceramic manufacturing, Chemical processing, Glass making.

These industries are characterized by high-energy demands and have traditionally contributed significantly to carbon emissions. The adoption of total burner solutions in these sectors demonstrates a commitment to sustainable practices and energy conservation. For instance, in the steel and aluminum industries, exhaust gasses can be lowered through a heat recovery system. These tools can dramatically reduce the energy required for melting and processing these metals.

In ceramic manufacturing, these solutions can enhance kiln efficiency, leading to lower fuel consumption and reduced production costs. Similarly, in glass making and chemical processing, the optimization of heat recovery processes ensures that energy is used judiciously, enhancing overall sustainability.

Saint-Gobain's Contribution to Heat Recovery and Energy Efficiency

Saint-Gobain, a leader in the development of high-performance refractory tools, offers a range of total burner solutions. These have been tailored for thermal waste treatment and waste-to-energy applications.

Available total burner solutions are designed to support industries in achieving enhanced heat recovery and energy efficiency, contributing to the reduction of carbon emissions.

By leveraging advanced materials, such as silicon carbide (SiC), Saint-Gobain's products offer superior durability and performance under extreme conditions. This makes them an ideal choice for industrial heating applications.

Total Burner Solutions Have A Variety of Industrial Applications

The adoption of total burner solutions represents a significant advancement in industrial heating processes.

Integrating technologies, such as ceramic recuperators, burner nozzles, and flame tubes, offers a path to improved energy efficiency and reduced carbon emissions. Their application across various sectors underscores the versatility and effectiveness of these technologies in meeting the demands of modern industrial operations.

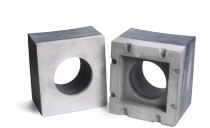

Burner Blocks and Burner Tubes

Discover Saint-Gobain Performance Ceramics & Refractories’ comprehensive range of burner blocks and burner tubes for copper furnaces.

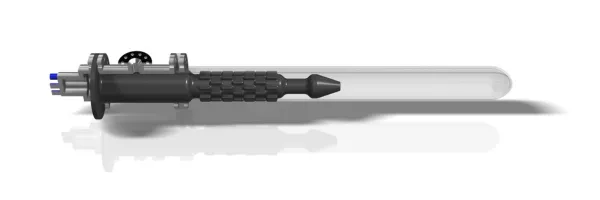

Amasic-3D Burner Nozzles

Discover Saint-Gobain Performance Ceramics & Refractories’ range of burner nozzles – ideal for guiding the flow of combustion.

PyroCor and Silit Flame Tubes

Discover Saint-Gobain Performance Ceramics & Refractories’ range of flame tubes and diffusers – ideal for guiding the flow of combustion.

SpyroCor and NOxBuster Radiant Tube Insert

Discover Saint-Gobain Performance Ceramics & Refractories’ range of radiant tube inserts – ideal for improving efficiency in the furnace chamber.

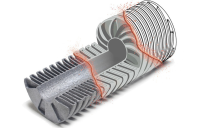

HeatCor and Silit Recuperators

Discover Saint-Gobain Performance Ceramics & Refractories’ range of recuperators for integration into burner systems.

As industries continue to seek sustainable and cost-effective methods of operation, the importance of total burner solutions in facilitating heat recovery and energy conservation cannot be overstated.

Saint-Gobain's contributions to this field highlight the potential of advanced materials and engineering in driving forward the agenda of environmental sustainability and operational efficiency.

Visit Saint-Gobain’s website to learn more about total burner solutions by clicking here.

Want to know more?

Contact our experts now to explore the development opportunities that await you. Click the button below to fill out the form, and we will be delighted to accompany you on your journey.