What our ceramic solutions are ?

Supporting You Throughout the Entire Creation Process

Features and Benefits

- ORE & COKE

- CHLORINATOR

- GAS CLEANING / DUST COLLECTION

- CONDENSATION / PURIFICATION

- OXIDATION

- COOLING

- MILLING

Key solutions

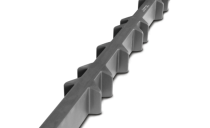

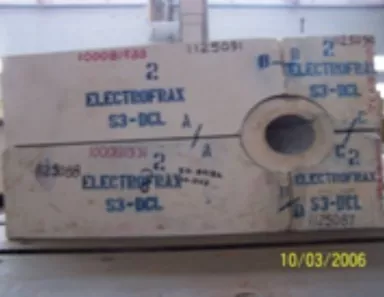

Saint-Gobain utilizes solid cast ceramic shapes from our Cryston® and Norfrax® to line the equipment that transports the raw materials to the chlorinator, including orifices, spools, tees, reducers, elbows, laterals, and feed nozzles. The ceramic solution replaces steel fittings giving a much longer wear life and can be designed to easily match up to existing fittings. The casting of ceramics eliminates the number of seams to offer improved wear performance versus solutions with multi joint designs.

These sleeves are manufactured from Cryston® and offer extended life versus cast metal shapes. The sleeves are used in the critical flow areas of the pump which is used to feed the raw material to the chlorinator. Typically three Cryston® sleeves are used in each pump

Key solutions

These nozzle liners are typically produced from Norfrax® RB and are used to connect the feed piping system through the refractory lining. When produced from ceramics such as Norfrax® RB, these nozzle liners can extend through the refractory lining to the hot face brick lining.

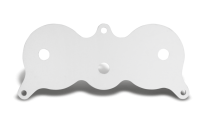

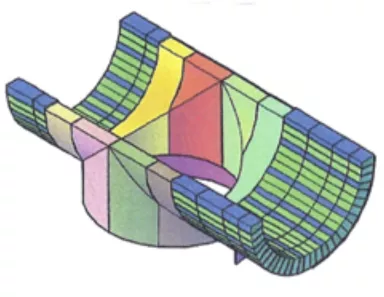

Produced from Saint-Gobain’s fused cast ceramic, ZAC®, the nozzle block assemblies can replace traditional refractory linings offering superior wear life due to the material performance as well as the dimensional quality of the product. The ZAC® blocks can be utilized in the high wear areas including the fluidized floors, man-way doors, feed nozzles, and high wear areas across from the feed nozzles

Key solutions

Key solutions

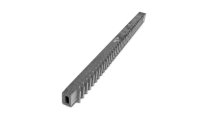

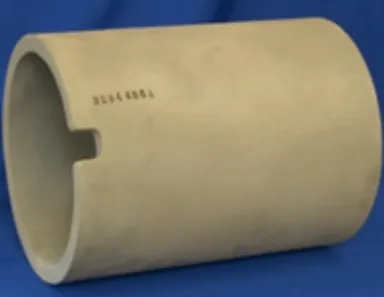

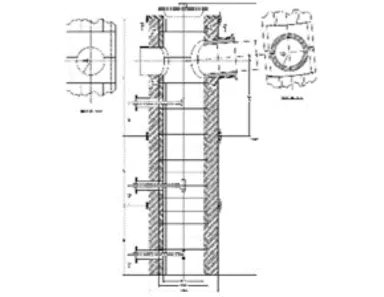

Depending on equipment sizes, Saint-Gobain can design a monolithic liner or a traditional brick design to line the inside of the various processing equipment. These linings are designed with perpendicular seams to improve the overall performance. Solid cylinders can also be incorporated in the inlet and outlet nozzles to reduce the overall number of joints in the lining system.

Key solutions

Key solutions

Saint-Gobain provides both Cryston® and Hexoloy® liners for various configurations of fittings in the cooling ponds. These fittings are lined with ceramics to help improve overall wear performance as well as help with heat transfer in the piping systems. Inlet transitions can be incorporated to maximize flow when using a square back elbow in the transitions.

Key solutions

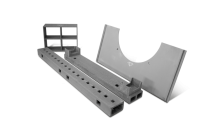

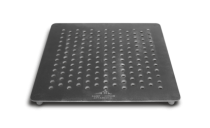

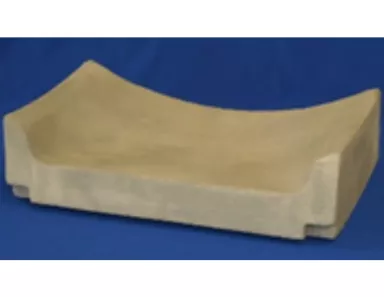

Titanium dioxide is milled to size utilizing high efficiency micronizers or jet mills. These mills are traditionally supplied in carbon steel. Utilizing Saint-Gobain’s Cryston® or Norfrax® RB, manufacturers can increase their mill life and reduce the possibly for contamination. Saint-Gobain can provide the mill liners in one piece designs for many different sized configurations.

Making the World a better home

Saint-Gobain Performance Ceramics and Refractories play an integral role within the Saint-Gobain Group. Our teams around the world share an ambitious and meaningful purpose: Making the World a Better Home.

A purpose that not only inspires but calls for action.

Poursuit of sustainability

Related Content

Systems for Kilns & Furnaces

Discover Saint-Gobain Performance Ceramics & Refractories’ comprehensive range of ceramic products and solutions - designed, developed, and manufactured...

Abrasives and Grinding Media

Discover Saint-Gobain Performance Ceramics & Refractories’ range of kiln furniture systems – ideal for the production of grinding wheels and grinding...

Hot Stamping

Discover Saint-Gobain Performance Ceramics & Refractories’ range of high-performance ceramic rollers – ideal for use in all roller hearth kiln zones and...

Sanitaryware and Dinnerware

Discover Saint-Gobain Performance Ceramics & Refractories’ sanitary and dinnerware solutions – advanced kiln furniture systems able to reduce energy...

Diesel Particle Filters and Gas Particle Filters

Discover Saint-Gobain Performance Ceramics & Refractories’ range of LO-MASS® kiln furniture - excellent strength, shape and assembly stability for large...

Lithium-Ion Battery Cathode Powders

Discover Saint-Gobain Performance Ceramics & Refractories’ range of high-strength silicon carbide rollers – suitable for roller hearth kilns used to...

Technical Ceramics Application

Discover Saint-Gobain Performance Ceramics & Refractories’ comprehensive range of engineered ceramics and refractories – highly suited to producing high...

Glass Technology

Discover Saint-Gobain Performance Ceramics & Refractories’ comprehensive range of refractories – highly suited to the production of high-quality, high...

Related Products

PowerCeram Saggers

Explore the benefits and features of PowerCeram® Saggers for CAM Processing.

LO-MASS® Kiln Furniture

Discover Saint-Gobain Performance Ceramics & Refractories’ comprehensive range of solutions and materials for kilns and furnaces, including kiln furniture...

Crystar® and Hexoloy® High-Load Beams

Discover Saint-Gobain Performance Ceramics & Refractories’ range of high-load beams - safe support in structural assemblies under extreme loads and at high...

N-Durance® Lavi Setters

Discover Saint-Gobain Performance Ceramics & Refractories’ comprehensive range of ceramic components for kiln car and kiln rack constructions – enabling...

N-Durance Lug posts

Discover Saint-Gobain Performance Ceramics & Refractories’ comprehensive range of ceramic components for kiln car and kiln rack constructions - enabling...

Nitride Bonded Silicon Carbide Plates & Batts

Discover Saint-Gobain Performance Ceramics & Refractories’ comprehensive range of ceramic components for kiln car and kiln rack constructions.

Crystar® Lug Posts

Discover Saint-Gobain Performance Ceramics & Refractories’ comprehensive range of ceramic components for kiln car and kiln rack constructions - enabling...

Crystar® Discs and Plate Setters

Discover Saint-Gobain Performance Ceramics & Refractories’ range of premium-quality recrystallized silicon carbide products – ideal for a wide range of...

Crystar® Rollers

Discover Saint-Gobain Performance Ceramics & Refractories’ range of Crystar® recrystallized silicon carbide rollers – ideal for use in high-temperature...

Silit® Rollers

Discover Saint-Gobain Performance Ceramics & Refractories’ range of Silit® silicon infiltrated rollers - optimal properties in a wide range of firing...

Hexoloy® Rollers

Discover Saint-Gobain Performance Ceramics & Refractories’ range of Hexoloy® silicon carbide rollers – ideal for use in high-temperature roller hearth...